Cold weather can vastly affect lifting equipment and it does so in a different way to hot temperatures. Metals, like many other materials, act differently in adverse temperatures. This can affect their strength, how they buckle and act with impact and how brittle they become too.

Because most types of lifting equipment contains metal components it can be affected by extreme temperatures. Most equipment will state minimum and maximum temperature ranges that they can be used in safely, so you must always check this out prior to use.

The unpredictability of metal is what can make it so dangerous, but buying the right lifting device for the cold conditions you work in and keeping a few things in mind, can keep you and your workers safe. Different types of metals can function well at certain low temperatures and factors like nickel content also need to be considered.

Steel and other metals can be hugely affected by their environment, so engineers and workers need to be aware of what can happen to heavy equipment moving tools and especially overhead lifting devices when cold weather happens. The breaking point of metal can change, so equipment like electric hoists can break before it has reached its maximum yield.

One of the main reasons this can be so dangerous is because the steel becomes more brittle. This means that at normal temperatures steel can buckle and show other signs it is about the break but when it is colder and the material more brittle, so can break with very little warning. This unpredictability certainly makes it a hazard for any tool lifting device.

These are great at absorbing energy and impact and will deform before they break, making them easier to work with.

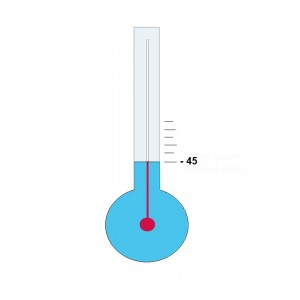

One of the most naturally occurring cold temperatures that manufacturers are often aware of is -45°. As one of the lowest temperatures that occur, andso many types of lifting gear can be operated safely down to this temperature.

There are countries all over the world which naturally reach very low temperatures. There are many parts of Canada which reach low temperatures and in all that snow, commercial and industrial operations still need to be underway.

Antarctica is the coldest place on earth, while other countries that might need specially designed lifting equipment to cope with cold weather could include Iceland, Greenland and Scandinavia. Also, places such as Russia and Kazakhstan reach startlingly low temperatures, where people are well accustomed to living and working in freezing, snowy conditions.

QT-100 (ASTM A514) is a type of material which is ideal for heavy machinery and vehicles and also works well at abnormal temperatures. Often used in large vehicle frames and chassis, this hugely strong alloyed steel should definitely be considered.

A great option and one often used by commercial industries in cold countries. It works well in naturally occurring cold temperatures such as -45°, so an aluminium gantry, for example, is appropriate to use in many cold countries with these sorts of conditions.

If you need material and that is durable in even lower temperatures then low carbon steel is a fantastic option. It is usually used at lows ranging from -75° to -100° Celsius, which is a substantial difference.

No matter what metal you opt for, if you want it to do well in the cold it has to have a high nickel content. A material containing 20% to 25% nickel is more stable compared to materials with those with lower nickel content. It is also not prone to cold cracking, even after welding. When looking for the best lifting devices, cranes or lifting chains for yourself, make sure you consider this important factor when searching for the right equipment.

While there is plenty of moving and lifting equipment out there that does operate in cold weather, you need to make sure that you have the right gear for your specific environment. Make sure that when assessing safe operating temperatures your engineer takes readings of the area you will be working in.

For many commercial engineers, it can be easy to say the minimum operating temperature is -20°. Opting for a less extreme temperature like this means less expensive and specialist equipment needs to be used, making operations more cost-effective. In many cases, even though the temperature can reach lower than -20°, the equipment used isn’t suitable for it. Not to mention testing and inspecting lifting equipment is also important, especially in abnormal conditions.

These kinds of situations emphasise the importance of correctly evaluating minimum temperatures in cold weather, finding out yourself and getting the right equipment.