Fully rotational with a pivoting anchor ring, the Yoke swivel lifting point offers a means of lifting loads without any evident anchor points.

Like all Yoke products these lifting points have been fully tested to ensure top quality and high safety factors. Made and tested to EN1677-1 conformity and certified by DGUV GS-OA 15-04. They also meet ASME B30.26 requirements.

Other testing procedures include proof and fatigue testing to 2.5 and 1.5 x the WLL respectively, giving a safety design factor or 4:1. Magnaflux crack detection has also been completed on this swivel eye bolt to 100%.

Made from individual forged parts and along with the screw cap are all traceable to test certification.

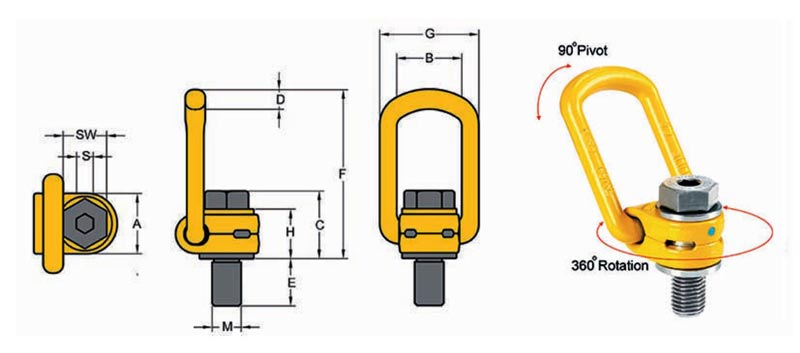

The main body can swivel through the full 360 degrees and the pivoting load ring moves through 90 degrees. This means that many loading angles can be safely achieved with this lifting point, although there may be some amendments to the working load limits required. Please consult the load tables below for complete clarity.

The Yoke swivel eyebolt is particularly suited for use with spreader beams and for lashing point attachments together with lifting slings. They may also be used in mold and die handling situations and also pump and valve handling.

Should you require some more information or advice you can get in touch with our team at 01384 76961. You can also email us through the contact form. Getting quotes can be done using both methods.

| Part Code | WLL tonnes |

Thread M mm |

A mm |

B mm |

C mm |

D mm |

E mm |

F mm |

G mm |

H mm |

S mm |

SW mm |

Torque in Nm |

Mass kg |

| 8-211-003G | 0.3 | M8 x 1.25 | 30 | 35 | 35 | 11 | 11 | 86 | 55 | 29 | 6 | 13 | 30 | 0.3 |

| 8-211-006G | 0.63 | M10 x 1.50 | 30 | 35 | 36 | 11 | 16 | 86 | 55 | 29 | 6 | 17 | 60 | 0.4 |

| 8-211-010G | 1 | M12 x 1.75 | 33 | 38 | 44 | 14 | 18 | 99 | 57 | 36 | 8 | 19 | 100 | 0.5 |

| 8-211-012G | 1.2 | M14 x 2.00 | 33 | 38 | 45 | 14 | 21 | 99 | 57 | 36 | 10 | 22 | 120 | 0.5 |

| 8-211-015G | 1.5 | M16 x 2.00 | 33 | 38 | 46 | 14 | 24 | 99 | 57 | 36 | 10 | 24 | 150 | 0.6 |

| 8-211-020G | 2 | M18 x 2.50 | 50 | 54 | 57 | 16 | 26 | 143 | 82 | 44 | 12 | 30 | 200 | 1.3 |

| 8-211-025G | 2.5 | M20 x 2.50 | 50 | 54 | 56 | 16 | 31 | 142 | 82 | 43 | 12 | 30 | 250 | 1.6 |

| 8-211-040G | 4 | M24 x 3.00 | 50 | 54 | 59 | 16 | 36 | 143 | 82 | 44 | 14 | 36 | 400 | 1.9 |

| 8-211-042G | 4 | M27 x 3.00 | 60 | 65 | 79 | 23 | 38 | 171 | 99 | 62 | 17 | 41 | 400 | 2.9 |

| 8-211-050G | 5 | M30 x 3.50 | 60 | 65 | 81 | 23 | 49 | 170 | 99 | 62 | 17 | 46 | 500 | 3.1 |

| 8-211-070G | 7 | M36 x 4.00 | 60 | 65 | 75 | 23 | 56 | 171 | 99 | 58 | 22 | 55 | 700 | 3.1 |

| 8-211-080G | 8 | M36 x 4.00 | 77 | 85 | 101 | 27 | 62 | 225 | 124 | 78 | 22 | 55 | 800 | 5.9 |

| 8-211-100G | 10 | M42 x 4.50 | 77 | 85 | 104 | 27 | 72 | 225 | 124 | 78 | 24 | 65 | 1000 | 6.3 |

| 8-211-150G | 15 | M42 x 4.50 | 95 | 104 | 112 | 36 | 64 | 258 | 158 | 86 | 24 | 65 | 1500 | 10.9 |

| 8-211-200G | 20 | M48 x 5.00 | 95 | 104 | 120 | 36 | 73 | 260 | 158 | 90 | 27 | 75 | 2000 | 12.1 |

| Part Code | WLL tonnes | Torque in Nm | Bolt Size | N.W. KG |

| LGD-211-003 | 0.3 | 30 | M8 x 1 x 1.25 x 45 | 0.2 |

| LGD-211-006 | 0.63 | 60 | M10 x 1.50 x50 | 0.3 |

| LGD-211-010 | 1 | 100 | M12 x 1.75 x 60 | 0.5 |

| LGD-211-012 | 1.2 | 120 | M14 x 2.00 x 60 | 0.5 |

| LGD-211-015 | 1.5 | 150 | M16 x 2.00 x 65 | 0.5 |

| LGD-211-020 | 2 | 200 | M18 x 2.00 x 75 | 1.3 |

| LGD-211-025 | 2.5 | 250 | M20 x 2.50 x 80 | 1.3 |

| LGD-211-040 | 4 | 400 | M24 x 3.00 x 85 | 1.4 |

| LGD-211-042 | 4 | 400 | M27 x 3.00 x 110 | 2.8 |

| LGD-211-050 | 5 | 500 | M30 x 3.50 x 115 | 3.1 |

| LGD-211-070 | 7 | 700 | M36 x 4.00 x 125 | 3.3 |

| LGD-211-080 | 8 | 800 | M36 x 4.00 x 140 | 5.8 |

| LGD-211-100 | 10 | 1000 | M42 x 4.50 x 150 | 6.3 |

| LGD-211-150 | 15 | 1500 | M42 x 4.50 x 160 | 10.9 |

| LGD-211-200 | 20 | 2000 | M48 x 5.00 x 170 | 11.6 |

WORKING LOAD APPLICATIONS

|

|

|

|

|

|

|

|

|||

| Number of leg | 1 | 2 | 1 | 2 | 2 | 2 | 3-4 | 3-4 | ||

| Load Direction | 0° | 0° | 90° | 90° | 0-45° | 45-60° | unsymm. | 0-45° | 45-60° | unsymm. |

| LGD-211-003 M8 | 0.3 | 0.6 | 0.3 | 0.6 | 0.42 | 0.3 | 0.3 | 0.63 | 0.45 | 0.3 |

| LGD-211-006 M10 | 0.63 | 1.26 | 0.63 | 1.26 | 0.88 | 0.63 | 0.63 | 1.32 | 0.95 | 0.63 |

| LGD-211-010 M12 | 1.0 | 2 | 1.0 | 2 | 1.4 | 1.0 | 1 | 2.1 | 1.5 | 1 |

| LGD-211-012 M14 | 1.2 | 2.4 | 1.2 | 2.4 | 1.7 | 1.2 | 1.2 | 2.5 | 1.8 | 1.2 |

| LGD-211-015 M16 | 1.5 | 3.0 | 1.5 | 3.0 | 2.1 | 1.5 | 1.5 | 3.1 | 2.2 | 1.5 |

| LGD-211-020 M18 | 2.0 | 4 | 2.0 | 4 | 2.8 | 2.0 | 2 | 4.2 | 3.0 | 2.0 |

| LGD-211-025 M20 | 2.5 | 5.0 | 2.5 | 5.0 | 3.5 | 2.5 | 2.5 | 5.2 | 3.7 | 2.5 |

| LGD-211-040 M24 | 4.0 | 8.0 | 4.0 | 8.0 | 5.6 | 4.0 | 4 | 8.4 | 6.0 | 4 |

| LGD-211-042 M27 | 4 | 8.0 | 4 | 8.0 | 5.6 | 4 | 4.0 | 8.4 | 6 | 4 |

| LGD-211-050 M30 | 5 | 10.0 | 5.0 | 10.0 | 7 | 5.0 | 5.0 | 10.5 | 7.5 | 5 |

| LGD-211-070 M36 | 7 | 14 | 7 | 14 | 9.8 | 7 | 7 | 14.7 | 10.5 | 7 |

| LGD-211-080 M42 | 8 | 16 | 8 | 16 | 11.2 | 8 | 8 | 16.8 | 12 | 8 |

| LGD-211-100 M42 | 10 | 20 | 10 | 20 | 14 | 10 | 10 | 21 | 15 | 10 |

| LGD-211-150 M42 | 15 | 30 | 15 | 30 | 21 | 15 | 15 | 31.5 | 22.5 | 15 |

| LGD-211-200 M48 | 20 | 40 | 20 | 40 | 28 | 20 | 20 | 42 | 30 | 20 |