Your shopping cart is empty!

The Yale HTP push travel beam trolley is a simple and easy to use beam attachment suitable for a range of beam profiles (I.e. INP, IPE, IPB) and can handle loads up to 5000kg.

PLEASE NOTE:

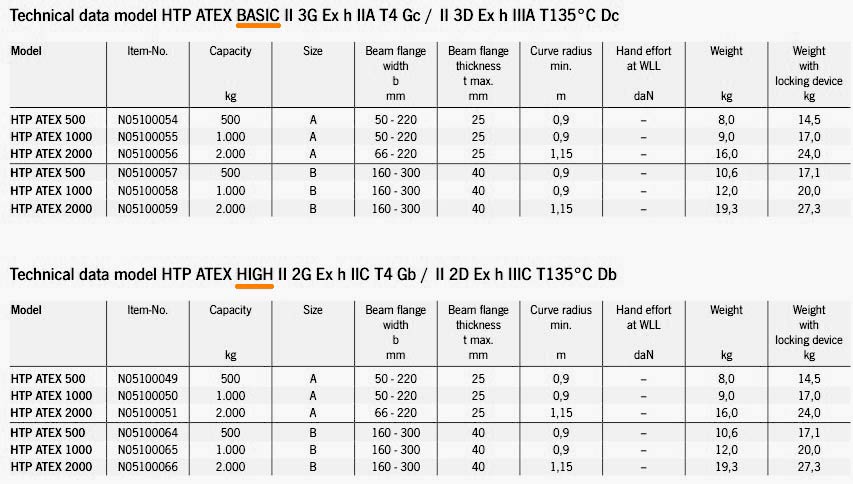

For hazardous environments there is the option of an ATEX rated version. Please get in touch for latest prices and delivery times.

The prices below are for the standard version

Two size ranges are available to suit beam widths, the size A range isfor smaller beams up to 220mm and type B for beams up to 300mm wide.

Fitting the trolley to a beam is relatively straightforward; you should allow between 1.0 & 2.5mm gaps between the wheel and beam flanges for optimum safety. There are three main components to the trolley for fitting, the clevis load bar, and two side plates which include the wheels.

Screw the adjusting load bar into the side plates one at a time until the bar just protrudes from the outer side. Additional spring washers and cylinder screws are needed for the type B trolleys (included).

Using the screw load pin, adjust the width to fit over the beam flange, when in position you can tighten up the side plates until the trolley fits correctly with the wheels in contact and with the correct spacing as stated above.

The load bar has a central lifting eye from where to fit your hoisting device, this must always be in the vertical position, never horizontal.

If you require an ATEX rated model (see specifications for full details) please give us a call or drop us an email for a quotation. Please note the bronze wheels are only on the high rated models, the basic models have an MKS micro corrosion protective coating.

You can find the technical details in the table below. If you need additional information on any beam trolley you can contact the team on 01384 76961. When you are ready you can add to cart to make an online purchase.

| Model | HTP 500-A | HTP 1000-A | HTP 2000-A | HTP 3000-A | HTP 5000-A | HTP 500-B | HTP 1000-B | HTP 2000-B | HTP 3000-B | HTP 5000-B |

| A, mm | 77 | 82.5 | 98.5 | 114 | 132.5 | 92 | 97.5 | 113.5 | 129 | 147.5 |

| D, mm | 16 | 17 | 22 | 26 | 33 | 16 | 17 | 22 | 26 | 33 |

| D1, mm | 25 | 30 | 40 | 48 | 60 | 25 | 30 | 40 | 48 | 60 |

| D2, mm | 30 | 35 | 47 | 58 | 70 | 30 | 35 | 47 | 58 | 70 |

| F1, mm | 46 | 46 | 46 | 46 | 45.5 | 46 | 46 | 46 | 46 | 45.5 |

| H1, mm | 30.5 | 30.5 | 30.5 | 30 | 30 | 45.5 | 45.5 | 45.5 | 45 | 45 |

| I (HTP), mm | 71.5 | 71.5 | 95.5 | 131 | 142.5 | 71.5 | 71.5 | 95.5 | 131 | 142.5 |

| L, mm | 260 | 260 | 310 | 390 | 450 | 260 | 260 | 310 | 390 | 450 |

| L1, mm | 130 | 130 | 150 | 180 | 209 | 130 | 130 | 150 | 180 | 209 |

| O, mm | 60 | 60 | 80 | 112 | 125 | 60 | 60 | 80 | 112 | 125 |

| P1, mm | 168 | 168 | 168 | 168 | 168 | 168 | 168 | 168 | 168 | 168 |

| P2, mm | 146 | 150 | 155 | 160 | 167.5 | 146 | 150 | 155 | 160 | 167.5 |

| L3, mm | 346 | 346 | 396 | 476 | 556 | 346 | 346 | 396 | 476 | 556 |

| Capacity (WLL) KG | Beam width mm | Weight KG | Capacity (WLL) KG | Beam width mm | Weight KG |

| Type ‘A’ | Type ‘B’ | ||||

| 500 | 50 - 220 | 8 | 500 | 160 - 300 | 10.6 |

| 1000 | 50 - 220 | 9 | 1000 | 160 - 300 | 12 |

| 2000 | 66 - 220 | 16 | 2000 | 160 - 300 | 19.3 |

| 3000 | 74 - 220 | 32 | 3000 | 180 - 300 | 35.8 |

| 5000 | 90 - 220 | 48 | 5000 | 180 - 300 | 52.2 |

ATEX MODEL SPECIFICATIONS