Lift, Pull, tension or position loads with the Tirfor T500 cable puller series. Three models are available, the T508 with working load limits to 800kg, the T516 with WLL to 1600kg and the T532 with working load limits of 3200kg.

Lightweight and quite compact the Tirfor 500 cable pullers can easily be handled and operated by a single person in any direction. Ideal for lighter duty tasks. The Tirfor TU models are better suited to heavier duty operations.

These Tirfors use a specific type of wire rope cable which can be of any length, although 20 metres is the usual standard. These long lengths should be handled with care to prevent kinks and twists in the rope which can cause issues. Wire rope should be kept on a reeler, this protects the cable but also helps with the handling.

Like most cable pulling machines the Tirfor 500 series can have the lifting and pulling capacity increased with the use of sheaves block pulleys. This is commonly known as the sheave block technique.

The Tirfor pulling winches use self actuating jaws to grip and pull the cable through. The heavier the load or force applied the tighter the jaws clamp. There is also a secure release system, ideal when threading and removing cable from the machine.

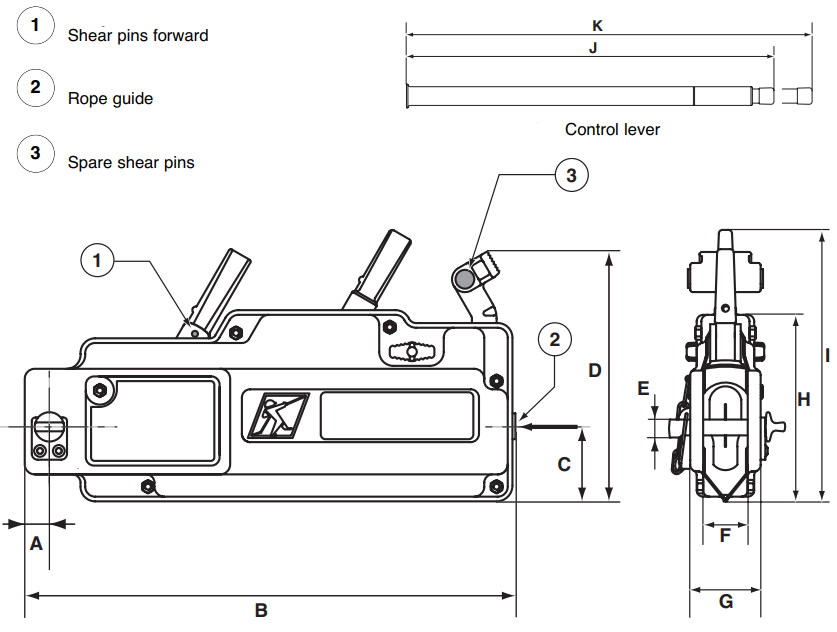

Overload protection comes in the form of sheer pins. An additional set is included as standard.

These machines are pretty simple to set up and operate. Firstly the machine needs to be secured to an appropriate anchor point, one that can take the pulling forces applied by machine and load.

There is a quick action anchor pin at the nose end of the cable puller. It is kept permanently attached to the machine body with a small chain to ensure it doesn't get lost. The pin incorporates a spring clip and sling design.

When it comes to installing the cable you will find a release mechanism, complete with an additional safety catch, to open the jaws so the rope can be pushed through without hindrance, the same applies when removing the rope. Don't forget to re-engage the jaws before continuing with your operation.

The cable can be advanced through the jaws in either direction, simply place the telescopic handle on either the forwards or reverse lever and crank with a back and forth motion.

Always read the operating manual before use, inspect your machine and rope regularly for issues and re-lubricated with the appropriate oil. (type SAE 90-120 is advised).

See the download manual for more correct operation, safety instructions, troubleshooting tips and more.

| Model | WLL | Rope Diameter | Effort to control lever | Rope Travel | Weight | ||

| kg | mm | forward kg | reverse kg | Forward mm | Reverse mm | kg | |

| T508 | 800 | 8.3 | 35 | 12 | 46 | 63 | 7 |

| T516 | 1600 | 11.5 | 48 | 18 | 42 | 57 | 14 |

| T532 | 3200 | 16.3 | 45 | 25 | 18 | 36 | 24 |

| Dimensions mm | |||||||||||

| Model | A | B | C | D | E | F | G | H | I | J | K |

| t508 | 20 | 420 | 64 | 212 | 15.3 | 38 | 60 | 165 | 230 | 405 | 690 |

| t516 | 30 | 530 | 77 | 252 | 21.3 | 50 | 84 | 193 | 315 | 648 | 1147 |

| t532 | 40.5 | 631 | 107 | 283 | 29 | 69 | 97 | 240 | 357 | 648 | 1147 |