The Stahl electric hoist range now revolves around one hoisting unit the ST hoist. Because it has been designed in a modular format the Stahl ST electric hoist can be configured in many ways in order to suit different types of lifting operations.

EXTENDED DELIVERY ON SOME MODELS. PLEASE CALL TO CHECK STOCK LEVELS BEFORE PLACING ORDERS.

The ST hoisting system can be configured for use in wind turbines, have ATEX rating, be configured as a dual hoist or as a big bag handling hoist and more, the options are vast. Read on for more details.

The standard Stahl St hoists are available in a wide range of lifting capacities, beginning at 125kg and going up to 6300kg. They boast two lifting speeds as standard and have FEM classification.

These hoists are compact so that available space can be utilised to maximum potential.

Probably the biggest benefit of the Stahl ST electric hoist is the suspension. The patented design ensures the highest safety levels due to the direct suspension on the cast iron chain guide, this ensures the that the load is supported directly where it engages.

The lower wear on the chain is ensured by the wear resistant chain sprocket and optimised return sheaves. The chain guide is also enclosed and self lubricating.

Only high quality components are used ensure excellent motor and brake systems. High duty cycle motors with fan cooling come as standard. Two hoist speeds permit precise positioning and single speed or four pole versions are available.

The asbestos free brake system requires little maintenance thanks to the completely enclosed electro-magnetic disc brake with oversized braking torque.

Overload protection on the ST hoist comes in the form of a slip clutch which is positioned in the oil cooled gear, and is easy to adjust from the outside.

There are a range of control options for the Stahl ST electric hoist including a more standard type pendant control, a remote radio controller or an RMI remote control (radioMOVEit remote control).

Other options available include SMC multi controller or SSC cumulative load control; Operational hoist limit switch; steel chain guides; bypass brake; vibration damper; load display and a slipping clutch test device. Contact us if you require more information on these optional extras.

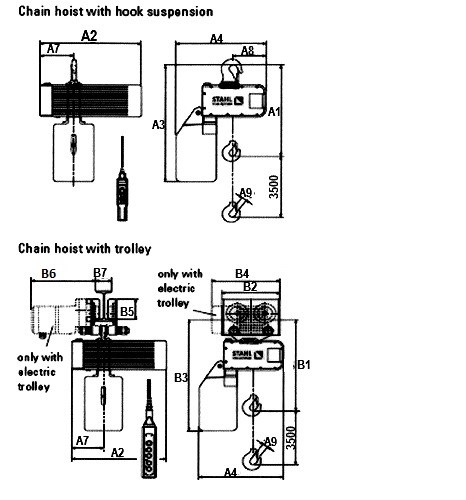

The Stahl ST has many options available when it comes to suspension and trolley systems. You can choose from rigid mounting, hook suspension or eye suspension. Hook suspension is the usual standard. Foot mounting options are also achievable.

Trolley options include a standard push travel type; DUE articulated for travelling around bends or electrically powered trolleys. The electric trolley comes as either a standard headroom, short headroom or extra short headroom options. (see images ). This is due to the hoist being fitted in different positions on the trolley systems.

If you would like to discuss any aspect of this or any other hoisting system or your lifting needs in general then contact the team at Lifting Gear Direct for help. We can supply electric hoists from all top brand names as well as offering servicing, repairs and inspections.

| KG | 250 | 500 | 1000 | 2000 | 3200 | 5000 | 6300 | |

| 2 hoisting speed | m/min | 08/02/24 | 04/01/24 | 04/01/24 | 04/01/24 | 04/01/24 | 3.2/0.75 | 3.2/0.75 |

| Chain falls | 1 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Type | ST 0502 | ST 0502 | ST 1005 | ST 2010 | ST 3016 | ST 5025 | ST 6032 | |

| Output | kW | 0.4/0.1 | 0.4/0.1 | 0.8/0.2 | 1.5/0.37 | 2.3/0.57 | 3.0/0.76 | 3.8/0.9 |

| Duty cycle | % ED | 50 | 50 | 60 | 60 | 60 | 60 | 50 |

| Dimensions (mm) | ||||||||

| Chain hoist with hook suspension | A1 | 367 | 428 | 432 | 547 | 575 | 697 | 697 |

| A2 | 238 | 238 | 402 | 496 | 496 | 522 | 522 | |

| A3 | 385 | 385 | 514 | 590 | 677 | 664 | 664 | |

| A4 | 281 | 281 | 352 | 398 | 393 | 466 | 466 | |

| A7 | 145 | 145 | 135 | 181 | 181 | 206 | 206 | |

| A8 | 153 | 153 | 133 | 158 | 158 | 154 | 154 | |

| A9 | 20 | 26 | 24 | 29 | 33 | 41 | 41 | |

| Chain hoist with trolley | B1 | 413 | 474 | 437 | 545 | 586 | 707 | 707 |

| B2 | 164 | 164 | 242 | 302 | 310 | 480 | 480 | |

| B3 | 425 | 425 | 519 | 589 | 689 | 672 | 672 | |

| B4 | / | / | / | 330 | 338 | 480 | 480 | |

| B5 | 62 | 62 | 96 | 102 | 113 | 149 | 149 | |

| B6 | 338 | 338 | 338 | 344 | 344* | 344* | 403* | |

| B7 | 42...180 | 42...180 | 58...300 | 66...300 | 66...300 | 82...300 | 82...300 | |

| Weights (kg) | ||||||||

| With hook suspension | 16 | 18 | 41 | 75 | 82 | 136 | 150 | |

| With trolley | 24 | 26 | 53 | 110 | 130 | 201 | 215 | |

| * The travel motor is mounted on the opposite side | ||||||||

| Capacity | FEM | m/min | Type | Motor data | ||

| kW | %ED | c/h | ||||

| 125 | 3m (M6) | 8/2 | ST 0501-8/2 1/1 | 0.2/0.05 | 35/15 | 240/480 |

| 250 | 1Am (M4) | 8/2 | ST 0502-8/2 1/1 | 0.4/0.1 | 35/15 | 120/240 |

| 500 | 1Am(M4) | 4/1 | ST 0502-8/2 2/1 | 0.4/0.1 | 35/15 | 120/240 |

| 8/2 | ST 1005-8/2 1/1 | 0.8/0.2 | 40/20 | 120/240 | ||

| 12/3 | ST 1005-12/3 1/1 | 1.2/0.3 | 40/20 | 120/240 | ||

| 1000 | 1Am (M4) | 4/1 | ST 1005-8/2 2/1 | 0.8/0.2 | 40/20 | 120/240 |

| 6/1.5 | ST 1005-12/3 2/1 | 1.2/.3 | 40/20 | 120/240 | ||

| 8/2 | ST 2010-8/2 1/1 | 1.5/0.37 | 40/20 | 120/240 | ||

| 12/3 | ST 2010-12/3 1/1 | 2.3/0.57 | 40/20 | 120/240 | ||

| 1600 | 1Bm (M3) | 8/2 | ST 3016-8/2 1/1 | 2.3/0.57 | 40/20 | 120/240 |

| (M5) | 8/2 | ST 3216-8/2 1/1 | 2.4/0.6 | 40/20 | 120/240 | |

| (M4) | 12/3 | ST 3216-12/3 1/1 | 3.8/0.9 | 33/17 | 100/200 | |

| 2000 | 1Am (M4) | 4/1 | ST 2010-8/2 2/1 | 1.5/0.37 | 40/20 | 120/240 |

| 6/1.5 | ST 2010-12/3 2/1 | 2.3/0.57 | 40/20 | 120/240 | ||

| 2500 | 1Am (M4) | 6.3/1.5 | ST 5025-6/1 1/1 | 3.0/0.76 | 40/20 | 120/240 |

| 8/2 | ST 5025-8/2 1/1 | 3.8/0.9 | 33/17 | 100/200 | ||

| 3200 | 1Bm (M3) | 4/1 | ST 3016-8/2 2/1 | 2.3/0.57 | 40/20 | 120/240 |

| 2m(M5) | 4/1 | ST 3216-8/2 2/1 | 2.4/0.6 | 40/20 | 120/240 | |

| 1Am(M4) | 6/1.5 | ST 3216-12/3 2/1 | 3.8/0.9 | 33/17 | 100/200 | |

| 5000 | 1Am (M4) | 3.2/0.75 | ST 5025-6/1 2/1 | 3.0/0.76 | 40/20 | 120/240 |

| 4/1 | ST 5025-8/2 2/1 | 3.8/0.9 | 33/17 | 100/200 | ||

| Chain collectors for greater lifting heights | |||

| Hoist type | Single fall | Two fall | Material |

| ST05 | 7 | 3.5 | Plastic |

| 25 | 12.5 | Textile | |

| 16 | 8 | Textile | |

| 22 | 11 | Textile | |

| ST32 | 6 | 3 | Plastic |

| 12 | 6 | Textile | |

| 20 | 10 | Textile | |

| ST30 | 6 | 3 | Plastic |

| 10 | 5 | Textile | |

| 20 | 10 | Textile | |

| ST50 | 8 | 4 | Textile |

| 12 | 6 | Textile | |

| 30 | 15 | Steel | |

| STANDARD | OPTIONS | ||

| Ambient Temperature | -20°c up to +40°c | to +50°c | |

| Protection to IEC/EN 60529 | IP55 | IP66 | |

| Paint | Colour | Greyish black/yellow-green RAL 7021/6018 | All other colours from RAL colour chart |

| DFT | 80μm | 120μm to 240μm | |

| Paint | Polyurethane topcoat | Epoxy-resin base (240μm) | |

| Control Pendants | STH 1 control pendant with emergency stop palm button | Radio remote control in push button or joystick version | |

| Move it one-hand control switch | |||

| Control | Contactor control including main contactor | For crane manufacturers, contactor control without transformer and without crane switch contactor | |

| Direct control (ST05-ST20) | |||

| Hoist motor control | Pole-changing | Frequency controlled | |

| Travel motor control | 50Hz | 20 m/min | 2.5/10 m/min and 5/20 m/min |

| 60Hz | 25 m/min | 3.2/12.5 m/min and 6.3/25 m/min pole-changing or frequency controlled | |

| Motor supply voltage | 50Hz/60Hz | 380-415V ST05 also 380-400V or 415V | All voltages possible |

| Chain | Grade 8 to DIN 5684 | Galvanised | Stainless steel chain, off-standard chain (hardened) |

| Safety Factor | >5.0 | / | |

| Chain Guide | Grey cast iron EN GJS | Sandwich chain guide made of hardened spring steel plates | |

| Chain box | Plastic, textile | Sheet steel | |

| Load lifting elements | |||