A scaffold crane or runway crane for scaffolding provides a means for lifting and moving loads both up and across a scaffolding tower. Whilst at the same time making the most use of your scaffolding. The sectional design and choice of trolleys and components enables customization to suit your requirements and scaffold system.

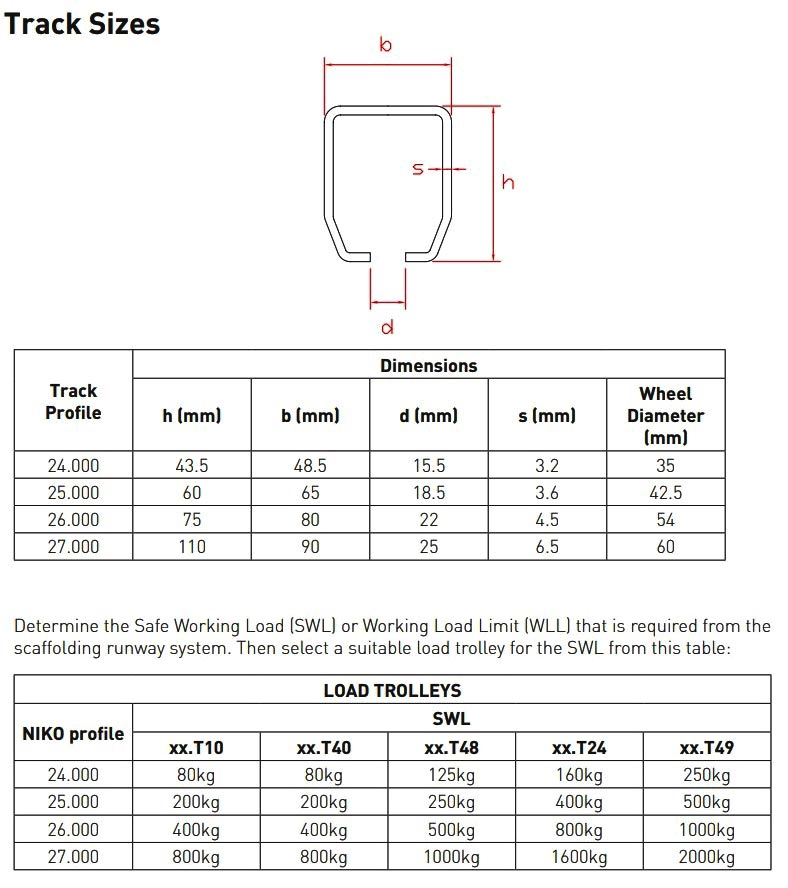

The track used in this scaffold runway crane system is light in weight for easy handling. You can easily install it, use it, then remove it and re-install it elsewhere. It is available in 3 or 6 metre lengths as standard although customised lengths can be accommodated. Multiple tracks can be connected with a joint support scaffold clamp to make longer tracks around the scaffold. The track also comes in various profile sizes ranging from 24 to 27. and safe working loads ranging from 100kg up to 2000kg.

Another option that this system is capable of is a cantilever section. This enables the end portion of the track to project out from the scaffolding by up to 1 metre, which can aid in lifting loads past building/scaffold projections or other obstacles which would hinder the lift. There are certain rules to adhere to if you use a cantilever runway and vary according to track profile size and length of projected cantilever section. You can find out more about this in the downloadable handbook in the tab above.

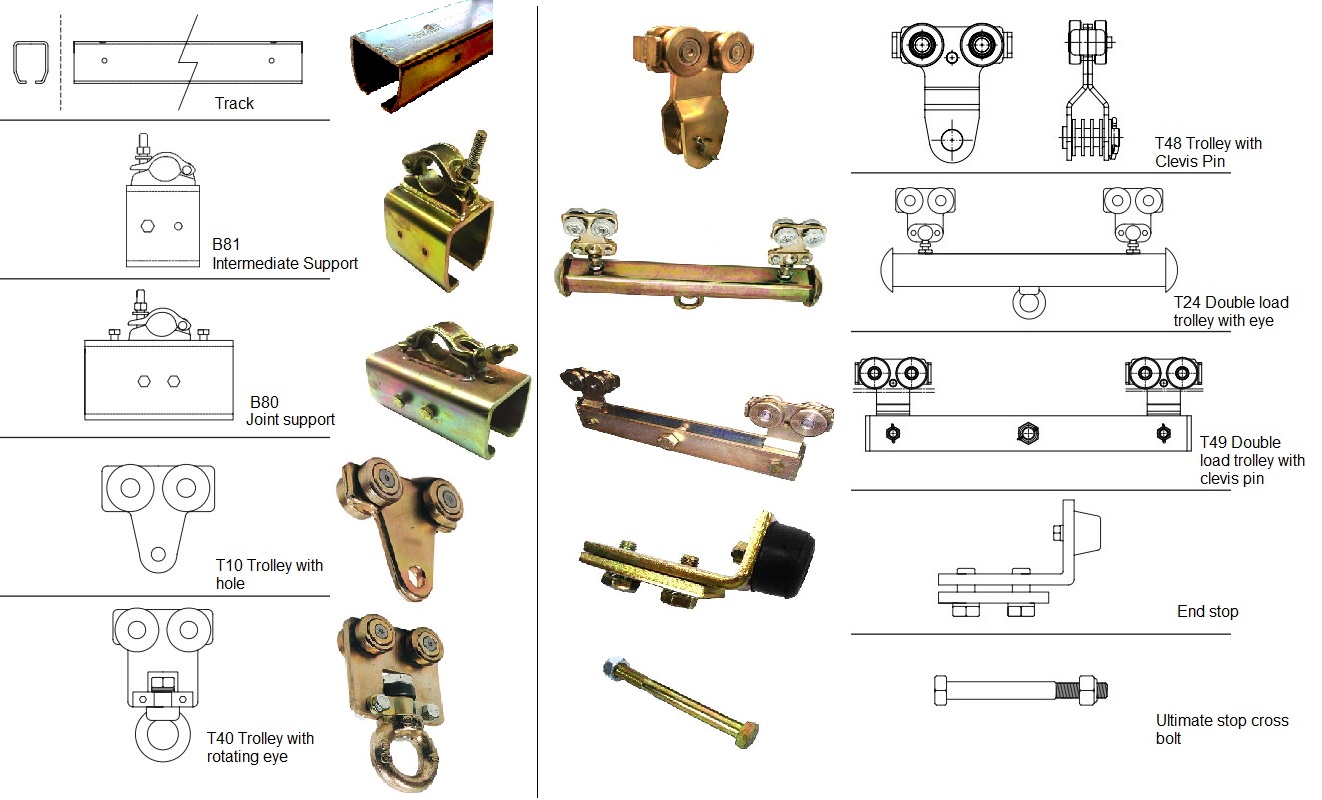

Dual purpose clamps are used to hold the track and connect it to the scaffold pole. Intermediate supporting clamps and joint support clamps (for connecting 2 tracks together) both incorporate a scaffold pole shaped clamp at the top which secures with a bolt. These clamps also both have a couple of pinch bolts to the sides which need to be tightened (although not overly so) to position and align the track whilst holding it secure. The joint support clamp has a set of additional bolts located at the top on each side of the scaffold pole clamp. These should be lined up with the ones at the track ends and screwed tightly to hold two pieces of track together.

End stops and ultimate stop bolts must be placed at each open end of track to prevent the trolley and hoist from running off the track.

As you can see from the image below there is a good choice of trolleys to compliment the scaffold crane. Each will have a specific safe working load depending on the track profile size, you can check the table in the download manual for all the specifics.

Building sites, constructing large and/or high structures will undoubtedly use some type of scaffolding system to enable access to the higher parts of the build from the outside. The scaffold cranes or scaffolding runway system that Lifting Gear Direct can offer enable you to lift your load to the top as well as across the length of the runway track. In other words (depending on the track length) you could lift up a loaded brick basket at the east side of the build and move it to the centre top or further to the west side depending on where the materials are needed. Materials, tools and rubbish can also be transported across and down to ground level when finished with.

Need to know more? No problem! give the team a call to discuss your requirements and they will provide you with an up to date quotation.

Not quite right for you! Browse the scaffold hoist collection to see a great range of hoists designed specifically for clamping onto a scaffold pole and there is a great selection of accessories to use with them such as liftable wheelbarrows and brick baskets.

Basic Specifications