Your shopping cart is empty!

There is a great selection of this Load Ring available with WLL up to 31.5 tonnes.

The VRBS Load Ring is for welding on and so therefore creates a permanent, secure fixing point. These load rings can be used individually or in multiples, depending on the load you need to fit them too. This enables lifting much larger loads and loads of awkward shaped and sizes.

Inspection and testing should take place by a competent person after initial welding to ensure it is safe to use. Thereafter frequent inspections should take place to ensure it remains safe to use. Checks for cracks, deformations and wear should be looked for.

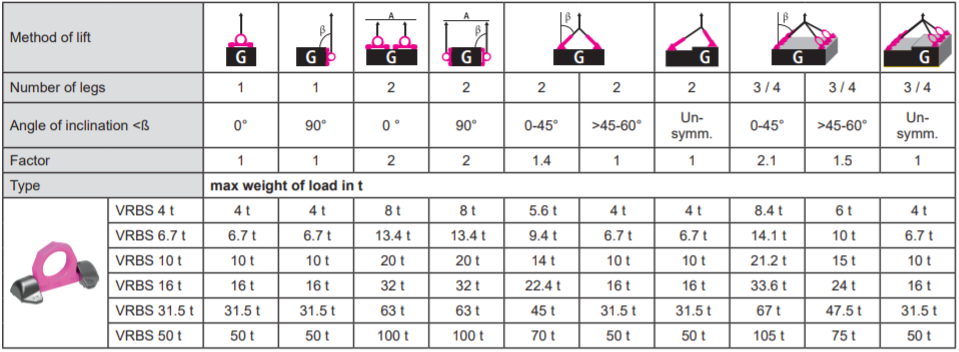

You should refer to the manufacturers lifting charts to ensure you use them in the correct manner. This is to ensure the centre of gravity of the load remains stable at all times.

Good distribution of the load force due to the 2 welding points. Welding should be done according to the manufacturers instructions by a qualified welder. This is because a specific sequence of welds are required. You should make sure the pivoting ring remains free to move.

These pivoting load rings have a low profile and lay flat when not used. They may be used in extreme temperatures from -40 degrees at the lower spectrum and up to +400 degrees C at the higher end.

They should not be used when chemicals such as acids are present in the environment.

There are many other types of eye bolts available across our website. There are many from RUD but we also supply eye bolts from other top manufacturers. Swivel and pivotal types are generally a bit more expensive but their additional benefits can outweigh this extra cost. We have many types of the more standard eyebolts available to purchase if the swivelling variety are not right for you.

You can contact the LGD team in a number of ways.

Either by phone or email, you can find the details on the contact page or at the top or bottom of each web page. You can also use the rapid enquiry form if you have any questions.

| Type | WLL (t) | A | B | C | D | E | F | O | Q | X | T | Weld | Weight (KG) | |

| VRBS 4 | 4 | 62 | 14 | 28 | 48 | 135 | 71 | 17 | 77 | 14 | 65 | HY 4 + 3 | 0.8 |  |

| VRBS 6.7 | 6.7 | 88 | 20 | 39 | 60 | 170 | 91 | 23 | 101 | 15 | 84 | HY 5.5 + 3 | 2.1 | |

| VRBS 10 | 10 | 100 | 22 | 46 | 65 | 195 | 100 | 28 | 106 | 22 | 95 | HY 6 + 4 | 2.8 | |

| VRBS 16 | 16 | 130 | 30 | 57 | 90 | 263 | 134 | 36 | 147 | 28 | 127 | HY 8.5 + 4 | 6.6 | |

| VRBS 30 | 30 | 160 | 42 | 78 | 130 | 373 | 195 | 47 | 220 | 37 | 178 | HY 15 + 4 | 19 | |

| VRBS 50 | 50 | 240 | 70 | 120 | 230 | 620 | 340 | 65 | 375 | / | 313 | HY 25 + 8 | 55 |