Here is the brand new Misia MH electric chain hoist which compliments the range of Misia wire rope hoists on offer at Lifting Gear Direct. It is a dual speed hoist with maximum lifting capacities of 2 tonne.

Misia are located predominantly in Milan, Italy, and have been producing electric wire rope hoists for over 35 years. Now to further extend their choice of hoisting equipment they have introduced the Misia MH electric chain hoist. The hoist is compact and easy to use yet rugged in design.

There are multiple configurations within the range which include choices of hook or eye suspension and a choice of push or electric trolleys should you require them.

Here is a quick look at the main features of the MH electric hoist.

125-2000Kg capacities

Dual Speed

3 phase motor

electro mechanical disc brake

Parallel shaft 3 stage gear box

Friction Clutch

Low voltage control panel with Schneider electromagnetic contactors

Push button control

Aluminium, die-cast body.

Galvanized load chain

Chain container

Push travel or electric trolley options

Hook or eye suspension

Now lets look at the key features in more detail.

Speeds:

There is a good range of lifting capacities to choose from, 125Kg, 250Kg, 500Kg, 1000Kg & 2000Kg. All models have dual lifting speeds, with all but the 2t model having the standard 8/2 speed options (SD). As alternative to the standard speed models there is a lower dual speed option (LD) of either 5/1.25 available for the 250, 500 models or 4/1 for the 1000 & 2000Kg models.

When deciding on the lifting speed you will need you should examine the types of load you will be lifting and the frequency they will be lifted. For example more delicate loads may benefit from the slower speeds but the need to lift many items in quick succession may benefit the faster speed.

Motor & Brake System:

The MH lifting hoist incorporates a powerful three phase motor with an asynchronous pole change and a cylindrical rotor. This has an F class insulation rating. The braking system uses the FD type disk brakes which are electro mechanical. A dust protection ring is incorporated in the brake design to offer great protection from dust and other particles and therefore improves both durability and hoist performance.

Gearbox & Clutch:

The gearbox boasts low noise output and is vibration free on operation. This is largely thanks to the Parallel shaft 3 stage gearbox which incorporates case hardened alloy steel helical gearing which transposes into super smooth transmission.

When it comes to safety, the friction clutch acts as the overload protection device and will slip at a preset torque to prevent damage to the hoist. The clutch is very robust and will only need to be reset after 20,000 slipping events.

Control Panel & Pendant:

The main control panel is 48v and has been built and wired according to EN 60204-32. This low voltage control board boasts a Schnieder electro-magnetic contactor which is a low consumption coil for excellent longevity but also makes for easy repair/replacement.

The panel is well protected as it is sealed inside the aluminium body of the hoist with a shock resistant plastic cover. A rubber gasket is also incorporated in order to provide its IP55 protection.

The pendant control device is ergonomic in design and easy to operate in one hand. There are just 3 buttons, up, down and the all important emergency stop button. This is protected to IP65 standards.

Chain:

The load chain on the Misia MH electric hoist is made from quality alloy steel (DAT G80)which has been galvanized for added wear and fatigue protection. The chain conforms to EN 818-7.

Chain containers are available in 2 sizes for all models. The size needed will depend on the height of lift and therefore the amount of chain required for your lifting operation. These durable plastic containers will hold all unused chain to facilitate a safer lifting operation

Alongside the key elements listed above, you can choose your preferred type of hoist suspension as well as adding a push travel or electric beam trolley if required.

Hoist Suspension:

Your choice of hoist suspension will depend on where you need to anchor it. Choose a hook suspension if you are going to attach it to a beam clamp or shackle type fitting. The hook enables quick fitting and is easy to remove. It incorporates a safety catch to ensure it stays in situ.

You can also choose an eye type suspension point which are great for semi-permanently attaching to a beam trolley. Ideal for when using in the same place for long periods.

Trolley Options:

There are 2 choices of Misia beam trolleys, which can be safely fitted to a beam on a gantry crane system or Jib crane for example. The first option is the standard push travel trolley which is manually pulled across the beam. This trolley is ideal for lighter loads. It is a single shaft trolley system featuring safety lugs and rubber bumpers. The wheel profiles are suitable for use on both flat or tapered beams. There are also geared travel trolley options (not Misia) available from the range of beam attachments at Lifting Gear Direct.

If you want effortless travelling loads across a beam them opt for the electric trolley. Your load can be traversed over the beam at the touch of a button and keeps manual load handling to a minimum. This reduces physical effort and strain placed on the body when manually handling loads. Therefore, although more costly initially the benefits to health whilst optimising output is perhaps one of the biggest benefits of all and will soon pay for itself. The electric powered trolley incorporates a travel limit switch as well as rubber bumpers and safety lugs. It can be used in flat or tapered beams.

You will soon be able to purchase the Misia MH electric chain hoist online, but for now all you need to do is give us a call, we will happily quote you over the phone or via email so let us know your choices, model, SWL, suspension and trolley type if required.

Don't forget we also supply the Misia wire rope hoists for heavy duty lifting operations. Or compare this hoist with similar ones from other manufacturers to ensure you get the best possible hoist to suit your needs.

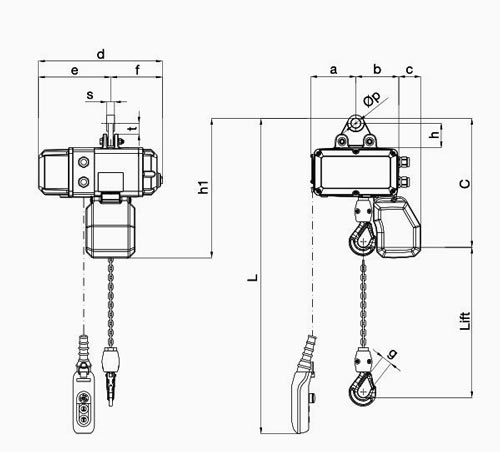

Eye Suspension Hoist Dimensions

| SWL | Model | Minimum Headroom C | Dimensions (mm) | |||||||||||

| t | eye suspension 1S | mm | a | b | c | d | e | f | g | h | h1* | s | t | øp |

| 125 | MH1SD/1S | 420 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 80 | 455 | 25 | 35 | 30.5 |

| 250 | MH3LD/1S | 420 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 80 | 455 | 25 | 35 | 30.5 |

| 250 | MH3SD/1S | 420 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 80 | 455 | 25 | 35 | 30.5 |

| 500 | MH5LD/1S | 420 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 80 | 455 | 25 | 35 | 30.5 |

| 500 | MH5SD/1S | 420 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 80 | 455 | 25 | 35 | 30.5 |

| 1000 | MH10LD/1S | 456 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 80 | 455 | 25 | 35 | 30.5 |

| 1000 | MH10SD/1S | 454 | 174 | 144 | 116 | 452 | 266 | 186 | 25 | 92 | 545 | 30 | 36.5 | 36.5 |

| 2000 | MH20LD/1S | 541 | 174 | 144 | 116 | 452 | 266 | 186 | 34 | 92 | 545 | 30 | 36.5 | 36.5 |

| * Short type container (up to 11m chain) | ||||||||||||||

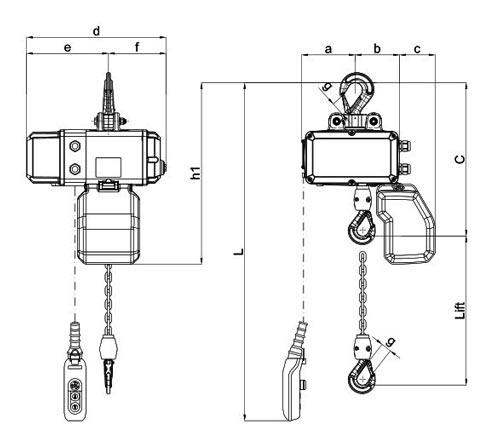

Hook Suspension Hoist Dimensions

| SWL | Model | Minimum Headroom C | Dimensions (mm) | |||||||

| t | Hook suspension 1G | mm | a | b | c | d | e | f | g | h1* |

| 125 | MH1SD/1G | 445 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 480 |

| 250 | MH3LD/1G | 445 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 480 |

| 250 | MH3SD/1G | 445 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 480 |

| 500 | MH5LD/1G | 445 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 480 |

| 500 | MH5SD/1G | 445 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 480 |

| 1000 | MH10LD/1G | 480 | 148 | 140 | 72 | 404 | 235 | 169 | 25 | 480 |

| 1000 | MH10SD/1G | 500 | 174 | 144 | 116 | 452 | 266 | 186 | 25 | 590 |

| 2000 | MH20LD/1G | 585 | 174 | 144 | 116 | 452 | 266 | 186 | 34 | 590 |

| * Short type chain container (up to 11m chain) | ||||||||||

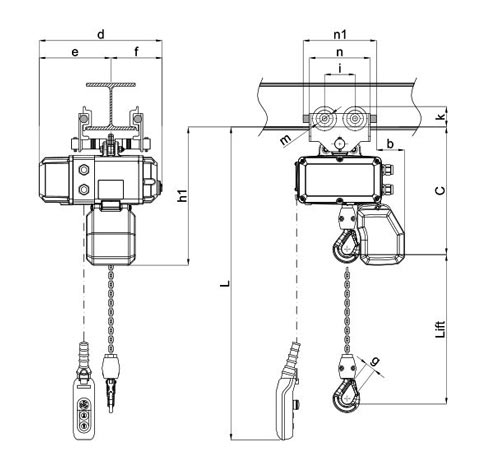

MH Hoist with Push Trolley Dimensions

| SWL | Model | Minimum Headroom C | Dimensions (mm) | ||||||||||

| t | 2S Push Travel Trolley | mm | b | d | e | f | g | h1* | I | m | n | n1 | k |

| 125 | MH1SD/2S | 425 | 92 | 404 | 235 | 169 | 25 | 460 | 100 | 55 | 200 | 240 | 67 |

| 250 | MH3LD/2S | 425 | 92 | 404 | 235 | 169 | 25 | 460 | 100 | 55 | 200 | 240 | 67 |

| 250 | MH3SD2S | 425 | 92 | 404 | 235 | 169 | 25 | 460 | 100 | 55 | 200 | 240 | 67 |

| 500 | MH5LD/2S | 425 | 92 | 404 | 235 | 169 | 25 | 460 | 100 | 55 | 200 | 240 | 67 |

| 500 | MH5SD/2S | 425 | 92 | 404 | 235 | 169 | 25 | 460 | 100 | 55 | 200 | 240 | 67 |

| 1000 | MH10LD/2S | 500 | 92 | 404 | 235 | 169 | 25 | 498 | 120 | 78 | 246 | 286 | 87 |

| 1000 | MH10SD/2S | 462 | 117 | 452 | 236.5 | 186.5 | 25 | 555 | 120 | 78 | 246 | 286 | 87 |

| 2000 | MH20LD/2S | 555 | 117 | 452 | 236.5 | 186.5 | 34 | 560 | 132 | 80 | 276 | 316 | 94 |

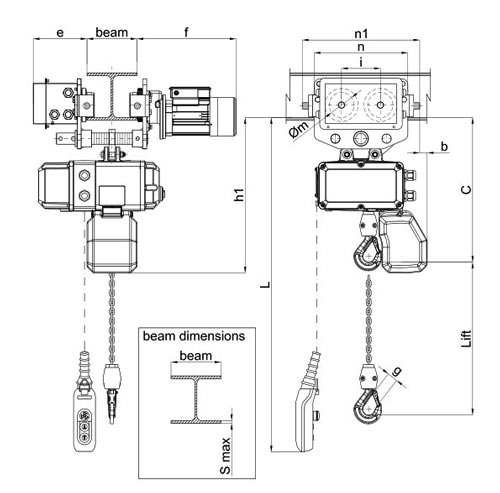

MH Hoist with Electric Powered Trolley Dimensions

| SWL | Model | Minimum Headroom C | Dimensions (mm) | ||||||||||

| t | 3 Electric Trolley | mm | c mm | e mm | f mm | g mm | h1* mm | I mm | m mm | n mm | n1 mm | k mm | s max mm |

| 125 | MH1SD/3 | 465 | 24 | 172 | 317 | 25 | 500 | 124.5 | 80 | 300 | 376 | 125 | 25 |

| 250 | MH3LD/3 | 465 | 24 | 172 | 317 | 25 | 500 | 124.5 | 80 | 300 | 376 | 125 | 25 |

| 250 | MH3SD/3 | 465 | 24 | 172 | 317 | 25 | 500 | 124.5 | 80 | 300 | 376 | 125 | 25 |

| 500 | MH5SD/3 | 465 | 24 | 172 | 317 | 25 | 500 | 124.5 | 80 | 300 | 376 | 125 | 25 |

| 500 | MH5SD/3 | 465 | 24 | 172 | 317 | 25 | 500 | 124.5 | 80 | 300 | 376 | 125 | 25 |

| 1000 | MH10LD/3 | 500 | 24 | 172 | 317 | 25 | 500 | 124.5 | 80 | 300 | 376 | 125 | 25 |

| 1000 | MH20LD/3 | 580 | 72 | 172 | 317 | 25 | 584 | 124.5 | 80 | 300 | 376 | 125 | 25 |

| 2000 | MH20LD/3 | 667 | 72 | 172 | 317 | 25 | 584 | 124.5 | 80 | 300 | 376 | 125 | 25 |

Eye Suspension

|

SWL |

Model Type 1S (eye suspension) |

Standard Lift |

Standard Push Button Cord “L” |

Chain Diameter x Falls |

Lifting Speed |

Power Supply |

Motor |

Classification |

Test Load |

Weight with 3m lift |

Weight + extra meter |

||

|

Output |

ED |

||||||||||||

|

t |

|

m |

m |

mm |

n° |

m/min |

|

kW |

% |

FEM |

t |

Kg |

Kg |

|

125 |

MH1SD/1S |

3 |

2.5 |

5 |

1 |

8/2 |

380-415V 50Hz |

0.09/0.36 |

40 |

2m |

156 |

35 |

0.55 |

|

250 |

MH3LD/1S |

3 |

2.5 |

5 |

1 |

5/1.25 |

0.09/0.36 |

40 |

3m |

313 |

35 |

0.55 |

|

|

250 |

MH3SD/1S |

3 |

2.5 |

5 |

1 |

8/2 |

0.09/0.36 |

40 |

1Am |

313 |

35 |

0.55 |

|

|

500 |

MH5LD/1S |

3 |

2.5 |

5 |

1 |

5/1.25 |

0.18/0.75 |

40 |

1Am |

625 |

35 |

0.55 |

|

|

500 |

MH5SD/1S |

3 |

2.5 |

5 |

1 |

8/2 |

0.18/0.75 |

40 |

1Am |

625 |

35 |

0.5 |

|

|

1000 |

MH10LD/1S |

3 |

2.5 |

5 |

2 |

4/1 |

0.18/0.75 |

40 |

1Am |

1250 |

37 |

1.1 |

|

|

1000 |

MH10SD/1S |

3 |

2.5 |

7 |

1 |

8/2 |

0.45/1.90 |

30 |

1Am |

1250 |

58 |

1.1 |

|

|

2000 |

MH20LD/1S |

3 |

2.5 |

7 |

2 |

4/1 |

0.45/1.90 |

30 |

1Am |

2500 |

61 |

2.2 |

|

Hook Suspension

|

SWL |

Model Type 1G (Hook suspension) |

Standard Lift |

Standard Push Button Cord “L” |

Chain Diameter x Falls |

Lifting Speed |

Power Supply |

Motor |

Classification |

Test Load |

Weight with 3m lift |

Weight + extra meter |

||

|

Output |

ED |

||||||||||||

|

t |

|

m |

m |

mm |

n° |

m/min |

|

kW |

% |

FEM |

Test Load |

Kg |

Kg |

|

125 |

MH1SD/1G |

3 |

2.5 |

5 |

1 |

8/2 |

380-415V 50Hz |

0.09/0.36 |

40 |

2m |

156 |

35 |

0.55 |

|

250 |

MH3LD/1G |

3 |

2.5 |

5 |

1 |

5/1.25 |

0.09/0.36 |

40 |

3m |

313 |

35 |

0.55 |

|

|

250 |

MH3SD/1G |

3 |

2.5 |

5 |

1 |

8/2 |

0.09/0.36 |

40 |

1Am |

313 |

35 |

0.55 |

|

|

500 |

MH5LD/1G |

3 |

2.5 |

5 |

1 |

5/1.25 |

0.18/0.75 |

40 |

1Am |

625 |

35 |

0.55 |

|

|

500 |

MH5SD/1G |

3 |

2.5 |

5 |

1 |

8/2 |

0.18/0.75 |

40 |

1Am |

625 |

35 |

0.5 |

|

|

1000 |

MH10LD/1G |

3 |

2.5 |

5 |

2 |

4/1 |

0.18/0.75 |

40 |

1Am |

1250 |

37 |

1.1 |

|

|

1000 |

MH10SD/1G |

3 |

2.5 |

7 |

1 |

8/2 |

0.45/1.90 |

30 |

1Am |

1250 |

58 |

1.1 |

|

|

2000 |

MH20LD/1G |

3 |

2.5 |

7 |

2 |

4/1 |

0.45/1.90 |

30 |

1Am |

2500 |

61 |

2.2 |

|

With Push Trolley

|

SWL |

Model Type 2S (Push Trolley) |

Standard Lift |

Standard Push Button Cord “L” |

Chain Diameter x Falls |

Lifting Speed |

Motor |

Classification |

BEAM WIDTH |

Min. radius curve |

Test Load |

Weight with 3m lift |

Weight + extra meter |

Power Supply |

|||

|

Output |

ED |

STD |

OPT |

|||||||||||||

|

t |

|

m |

m |

mm |

n° |

m/min |

kW |

% |

FEM |

mm |

mm |

mm |

t |

Kg |

Kg |

|

|

125 |

MH1SD/2S |

3 |

2.5 |

5 |

1 |

8/2 |

0.09/0.36 |

40 |

2m |

62-152 |

153-305 |

800 |

156 |

41 |

0.55 |

380-415V 50Hz |

|

250 |

MH3LD/2S |

3 |

2.5 |

5 |

1 |

5/1,25 |

0.09/0.36 |

40 |

3m |

62-152 |

153-305 |

800 |

313 |

41 |

0.55 |

|

|

250 |

MH3SD/2S |

3 |

2.5 |

5 |

1 |

8/2 |

0.09/0.36 |

40 |

1Am |

62-152 |

153-305 |

800 |

313 |

41 |

0.55 |

|

|

500 |

MH5SD/2S |

3 |

2.5 |

5 |

1 |

5/1,25 |

0.18/0.75 |

40 |

1Am |

62-152 |

153-305 |

800 |

625 |

41 |

0.55 |

|

|

500 |

MH5SD/2S |

3 |

2.5 |

5 |

1 |

8/2 |

0.18/0.75 |

40 |

1Am |

62-152 |

153-305 |

800 |

625 |

41 |

0.5 |

|

|

1000 |

MH10LD/2S |

3 |

2.5 |

5 |

2 |

4/1 |

0.18/0.75 |

40 |

1Am |

80-203 |

204-305 |

900 |

1250 |

48 |

1.1 |

|

|

1000 |

MH10SD/2S |

3 |

2.5 |

7 |

1 |

8/2 |

0.45/1.90 |

30 |

1Am |

80-203 |

204-305 |

900 |

1250 |

70 |

1.1 |

|

|

2000 |

MH20LD/2S |

3 |

2.5 |

7 |

2 |

4/1 |

0.45/1.90 |

30 |

1Am |

106-203 |

204-305 |

1000 |

2500 |

80 |

2.2 |

|

With Electric Trolley

|

SWL |

Model Type 2S (Push Trolley) |

Standard Lift |

Standard Push Button Cord “L” |

Chain Diameter x Falls |

Lifting Speed |

Lifting Motor |

Trolley Speed |

Trolley Motor |

Classification |

BEAM WIDTH |

Min. radius curve |

Test Load |

Weight with 3m lift |

Weight + extra meter |

||||

|

Output |

ED |

Output |

ED |

STD |

OPT |

|||||||||||||

|

t |

|

m |

m |

mm |

nº |

m/min |

kW |

% |

m/min |

kW |

% |

FEM |

mm |

mm |

mm |

t |

Kg |

Kg |

|

125 |

MH1SD/3 |

3 |

2.5 |

5 |

1 |

8/2 |

0.09/0.36 |

40 |

10-20 20/5 |

0.18-0.25 0.15/0.037 |

40 |

2m |

55÷200 |

55÷305 |

800 |

156 |

76 |

0.55 |

|

250 |

MH3LD/3 |

3 |

2.5 |

5 |

1 |

5/1,25 |

0.09/0.36 |

40 |

40 |

3m |

55÷200 |

55÷305 |

800 |

313 |

76 |

0.55 |

||

|

250 |

MH3SD/3 |

3 |

2.5 |

5 |

1 |

8/2 |

0.09/0.36 |

40 |

40 |

1Am |

55÷200 |

55÷305 |

800 |

313 |

76 |

0.55 |

||

|

500 |

MH5SD/3 |

3 |

2.5 |

5 |

1 |

5/1,25 |

0.18/0.75 |

40 |

40 |

1Am |

55÷200 |

55÷305 |

800 |

625 |

76 |

0.55 |

||

|

500 |

MH5SD/3 |

3 |

2.5 |

5 |

1 |

8/2 |

0.18/0.75 |

40 |

40 |

1Am |

55÷200 |

55÷305 |

800 |

625 |

76 |

0.55 |

||

|

1000 |

MH10LD/3 |

3 |

2.5 |

5 |

2 |

4/1 |

0.18/0.75 |

40 |

40 |

1Am |

55÷200 |

55÷305 |

900 |

1250 |

85 |

1.1 |

||

|

1000 |

MH20LD/3 |

3 |

2.5 |

7 |

1 |

8/2 |

0.45/1.9 |

40 |

40 |

1Am |

60÷200 |

60÷305 |

900 |

1250 |

106 |

1.1 |

||

|

2000 |

MH20LD/3 |

3 |

2.5 |

7 |

2 |

4/1 |

0.45/1.9 |

40 |

40 |

1Am |

60÷200 |

60÷305 |

1000 |

2500 |

116 |

2.2 |

||