Construction sites nearly always use scaffolding to reach the higher levels of a build but getting materials up there and moving them around can be quite tricky and often hazardous. A scaffold runway system will sort out this problem. Fit the lightweight beam to the scaffolding then attach your hoist and you're good to go. We can supply everything you need for the scaffolding runway, with track lengths around 3 metres together with joining components, pretty much any length can be accommodated. Lift your loads over the edge of the build and move them along the beam to where they are needed, simple!

POA

About Scaffold Crane Systems The track used in this scaffold runway crane sys..

A scaffold runway system is a specialised device which fits onto scaffolding to create a crane. Modular in design these lightweight scaffold cranes can easily be configured to suit your requirements and scaffolding structure. Once the beams are configured and fitted to the scaffold poles, a hoist and trolley system can be easily added to make lifting your materials quick and easy.

Scaffolding towers on construction sites are common place due to the fact that materials need to be taken to high levels on most builds. The larger the building under construction the larger and taller the scaffolding will need to be. Getting your materials up to these heights is one thing but moving them around the high levels is something else.

With a scaffolding runway system not only can you lift your materials to the required level but you can also traverse them across the runway beam to another location. Loads of up to 2000kg can be handled with this system.

This can save oodles of time whilst minimising manual effort and therefore risk of injuries.

As mentioned before this system has been cleverly designed in a modular format so that it can be configured and fitted to best suit your needs.

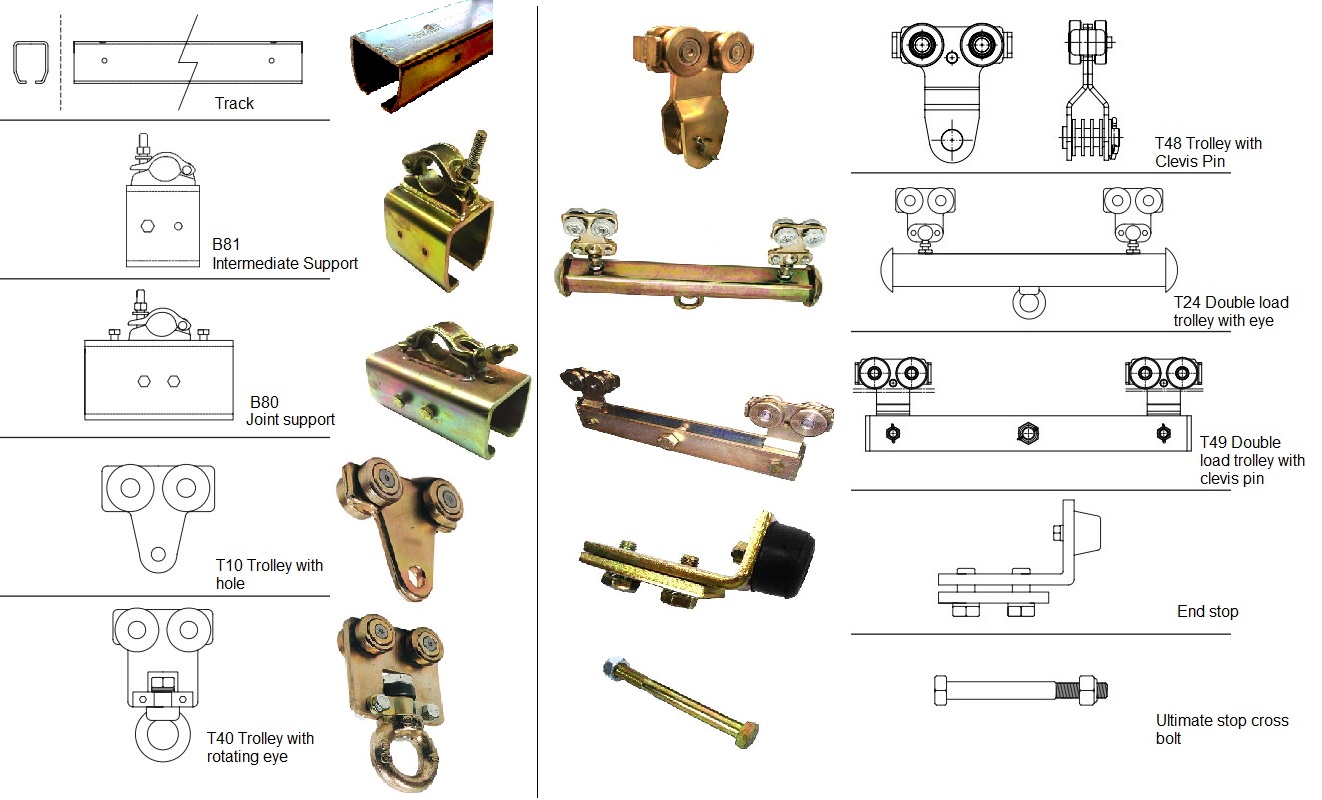

First and foremost there is the track, this comes in 3m lengths and in a range of profile sizes from 24.000 – 27.000. Two or more tracks can be joined with a special joint support clamp to make longer tracks.

There are the main clamps for attaching the runway beam onto the scaffolding poles with intermediate supports to add extra supporting strength to the mid section of the lightweight track.

It is also possible form a cantilevered track to provide an overhang however this needs to be set up specifically according to the manufacturers instructions which you can find in the downloadable handbook.

End stops should be fitted to each end to prevent the trolley from falling off the beam. There are a few different trolley types to choose from including double load trolley systems to suit a variety of needs.

These scaffold runway systems are supplied as a kit with all components as to your specifications, this means the runway can be put up, taken down and re-located with relative ease, so that you can use it in any area you wish.

Lifting Gear Direct can supply a choice of hoisting devices to suit these scaffold runway cranes. You will find a vast choice of electric hoists from all the key manufacturers. Should this set up not be right for you then why not take a look at our scaffold hoist and builders gantry hoist categories where you will find a great collection of hoists to fit directly to scaffolds or to a gantry trestle frame. These also have a great choice of accessories from brick baskets to tipping buckets, hoist clamps to wheelbarrow slings.

A scaffold runway system is essentially a crane system designed specifically to fit onto scaffolding. A lightweight beam with special scaffold clamps means the runway beam can be fitted to suitable scaffolding in most locations, thus creating a suspended runway from which you can fit a beam trolley and hoisting system to lift and move your loads anywhere within the range of the beam length.

Scaffold runway beams are supplied typically in 3 metre lengths, sometimes 6 metres. Joining multiple beams is possible using special joint connections, therefore many lengths are possible, bearing in mind the strength of the scaffolding and weights of the beam, lifting devices and loads to be lifted.

Our scaffold runway system can handle loads between 100kg and 2000kg thanks to the choice of beam profile sizes.