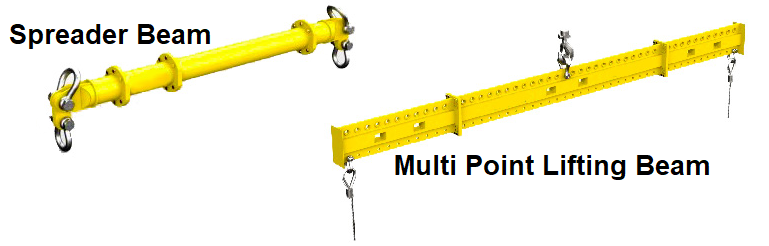

Lifting beams and spreader beams offer a means of lifting larger loads from one hoist or crane. The type you choose will depend on the load and method of lifting, as they are used differently. We offer a range of modular beams for true versatility and optimum strength.

POA

About Modular Spreader Beams When you need to lift multiple wider loads that ..

POA

Multi Point Lifting Beam Features and Benefits Being of a modular design, the..

The key difference between lifting and spreader beams is how they are anchored to the hoisting equipment, how they accommodate the size and weight of the load and most importantly, how and where they process the forces applied by the load. Lifting beams put what's called a bending stress on the beam, whereas a spreader beam puts what's known as a compression stress on the beam.

A standard lifting beam fits to the hoist/crane from a central point whereas a spreader beam has two attachment points, thus spreading the forces or the load across the beam quite differently. Spreader beams are typically much stronger and provide a well balanced load when used correctly. Find out more about each type below.

There are quite a few different varieties of these beams including standard, fixed sized and the more versatile modular variety, multi point beams are a more modern design which allow them to be used as a lifting beam or semi-spreader beam. Lifting Gear Direct can currently supply modular spreader beams with adjustable lengths and multi point lifting beams.

Lifting beams prove the better option when headroom is more limited and are typically a good option for shorter spans. The standard variety are rigid and heavy making them more difficult to handle and transport. They can only be anchored from one fixed central top lifting eye, which can affect load balance.

This is where the multipoint lifting beam comes into play. With capacities up to 110tonnes the modular design means its three sections can be unbolted for easier transportation, what's more the beam can be used with 1, 2 or all 3 of the sections thanks to the multiple lifting and loading points across the top and bottom of the beam. This means that your shackle or swivel hooks can be positioned to suit your application.

This multi-point lifting beam can be used as a standard beam for low headroom scenarios, for tandem lifts and as a semi-spreader beam. This is a truly versatile lifting beam option.

More details on the multi-point lifting beam product page.

Spreader beams are so called because they spread the forces implied by the load across the whole beam using compressive stress, thus usually stronger because there is no singular stress point.

Loading slings below the beam can be kept below 90 degree angles to ensure even weight distribution as long as the centre of gravity is aligned. Due to having 2 top anchoring points a spreader beam may not be suitable where headroom is limited. There are only two loading points on a spreader beam whereas the multi-point lifting beam can have multiple.

Lifting Gear Direct can supply the modular spreader beam in up to 110 tonne capacities, and which can be used in various length configurations. This means it can be used for many different load types. The bolt together sections also mean transporting and handling the beam is easier.

Besides these lifting and spreader beams we custom build our own lifting gantry systems as well a range of Jib cranes, both of which provide a lifting frame work from which to attach hoisting equipment to lift your load. Whilst the Jib cranes are of a fixed design our gantries can be mobile so they can be moves easily to different areas of your workplace. Be sure to check out the relevant product pages for all the details.