The design and specifications of the heavy duty L4 pull winch meets or exceeds international standards in the UK, EU, USA, AUS and S. Africa. They can be operated with safety in a wide range of temperatures, from minus 40 up to +55 degrees C.

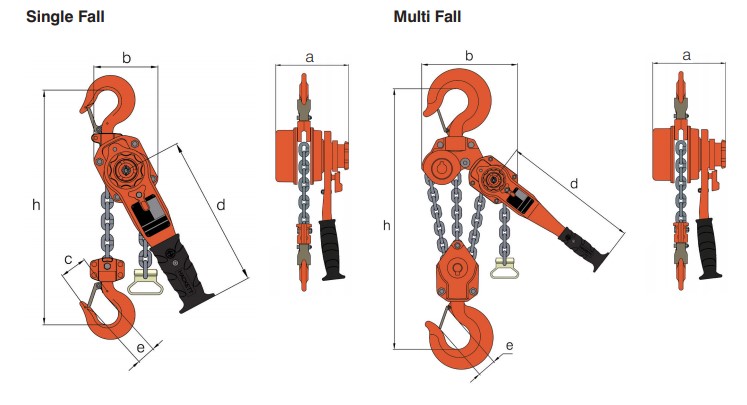

There are 7 models in the L4 range with incremental working load limits starting at 0.8 tonnes and going up to a huge 20 tonnes. The number of chain falls varies according to the model & lifting capacity with the smallest having 1 chain fall and the largest having 8 chain falls.

The size of the chain also differs across the range to suit the weight of the load; each hoist comes with 1.5 metres height of lift as standard, though other options are available.

Twin pawls, fitted as standard ensure optimum safety. Heavy duty safety latches are fitted to the top and bottom hooks and create a strong closure to ensure the anchorage of the hoist and load remain firmly engaged.

Another beneficial safety feature of this ratchet lever hoist is the overload indicator markings. These are positioned on both hooks, either side of the throat hook. The distance in-between these markings can be measured to see whether any stretch has occurred, if it has then it may have been overloaded and needs checking by a qualified person to see if replacement is necessary.

The housing for the hooks use socket head cap screws/hex head bolts and nyloc locking nuts to secure them.

Travelling end stops are available as an optional extra; this can be fitted in place of the standard end stop. This travelling stop can be moved along slack chain and relocated next to the body. The main benefits of this is to shorten the slack chain as well as stopping a possible run of load chain through the lever hoist when next used.

This Hacketts L4 model is a heavy duty lever hoist; proof loaded to 1.5 x S.W.L.

Call 01384 76961 to talk to our team, they will endeavour to answer your questions and provide a quotation on request. We can also supply additional lifting equipment which you may need to complete your job. Beam clamps and beam trolley’s provide an easy means of fitting the hoist to a crane and lifting slings and shackles make load securing easier and they are all readily available.

|

WLL |

a |

b |

c |

d |

e |

h |

i |

|

0.8 |

148 |

121 |

37.5 |

265 |

28 |

280 |

14.3 |

|

1.6 |

165.5 |

141 |

47 |

350 |

33 |

350 |

20 |

|

3.2 |

194.5 |

178 |

62.5 |

415 |

42.5 |

420 |

24.8 |

|

6.3 |

194.5 |

228 |

78 |

415 |

51 |

570 |

33.8 |

|

9 |

194.5 |

310 |

- |

415 |

56 |

680 |

42.2 |

|

15 |

194.5 |

420 |

- |

415 |

80 |

1000 |

59.2 |

|

20 |

194.5 |

480 |

- |

415 |

80 |

1150 |

- |

|

WLL |

No. of Falls |

Load Chain |

Standard |

Mass Kg |

Extra Weight |

|

0.8 |

1 |

5.6 x 17 |

1.5 |

6.2 |

0.7 |

|

1.6 |

1 |

7.1 x 21 |

1.5 |

9.6 |

1.1 |

|

3.2 |

1 |

10.0 x 30 |

1.5 |

15.5 |

2.2 |

|

6.3 |

2 |

10.0 x 30 |

1.5 |

27 |

4.4 |

|

9 |

3 |

10.0 x 30 |

1.5 |

38.3 |

6.6 |

|

15 |

6 |

10.0 x 30 |

1.5 |

90 |

13.2 |

|

20 |

8 |

10.0 x 30 |

1.5 |

195 |

19.2 |