The Ultralift E or ULE lifting magnet from Eclipse can lift flat plate up to 1000kg and round bar up to 500kg.

The Latest Eclipse ULE Lifting Magnet is capable of lifting ferro-magnetic materials whether flat or cylindrical.

The ULE lifting magnet incorporates a locking lever. This enables you to manually switch the magnet on and off. This locking switch/lever possesses a safety lock to ensure it can not be unintentionally operated.

The safety ratio for this magnetic lifter is 3:1 so you can be confident that lifts will hold firm as long as all the relevant criteria is met.

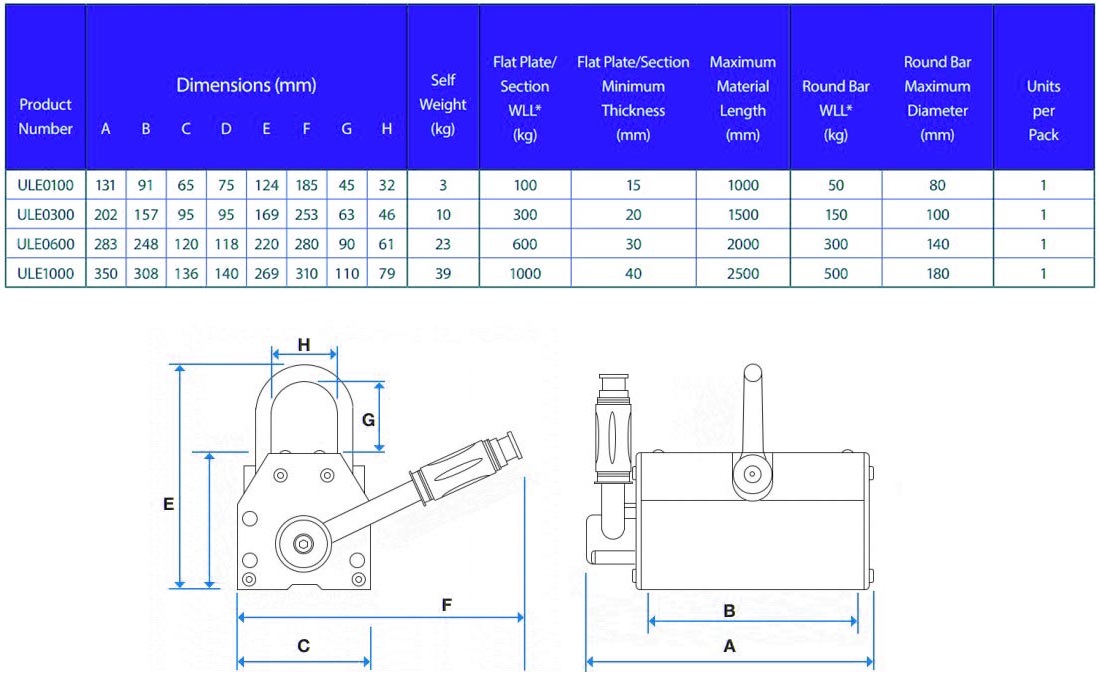

There are four models available which have differing working load limits as well as minimum plate thicknesses and maximum cylinder diameters allowed.

It is highly important to stick to the figures shown in the specification table. Especially the minimum plate thickness for flat steel plates. This is because the thinner the plate the less holding force will be achieved.

When used on round/cylindrical bars there will be maximum diameter limits for each model. This is to ensure the magnet can grip enough surface area to hold securely. Again please consult the specifications or downloadable PDF manual which has much more information regarding thicknesses.

If you need to lift thinner plates then take a look at the Eclipse TP range.

The Eclipse ULE magnetic lifter can be safely used in temperatures ranging from minus 10 to + 40 degrees Celsius or 14 to +104 degrees Fahrenheit.

It is important to note that all facts and figures shown are based on lifting high quality mild steel and that air gaps will produce varying results.

Always ensure loads are balanced and lifted vertically, using multiple magnets with a spreader bar for longer plate to prevent flexion.

As for maintenance, the same goes for all magnets, keep clean, inspect regularly, ensure there is no damage and test lift each time to ensure the magnet is functioning as it should. According to LOLER a thorough inspection must take place at the minimum every twelve months.

Order your magnetic lifter today from Lifting Gear Direct, call 01384 76961.today