The Dynafor Industrial load cell is a rebrand of the LLZ2 keeping the same trusted technology and integral display.

Load capacities up to 20 tonnes are available from Lifting Gear Direct.

Ideal

for many industrial applications the Dynafor industrial load cell is

a robust load measuring device with its own integrated display.

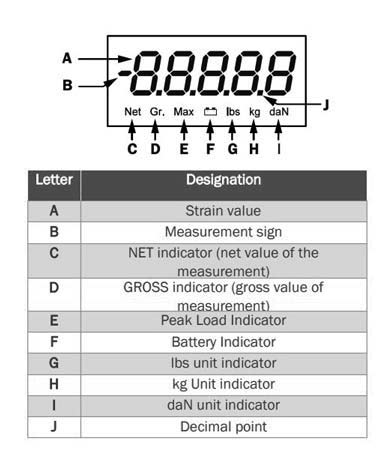

The display shows many measurements including strain value, net and gross indicators, peak load, lbs, kg and daN. There is also a battery indicator so you will quickly know when the 2 x AAA batteries need changing.

This versatile load measuring device works using the strain gauge extension means with the incorporated sensors sending the relevant signals to the in-built micro processor and subsequently to the display. The display has a range of functions such as on/off, tare, peak hold, automatic zeroing and the units of measurements in lbs or kg and forces in daN. There is also an automatic stop (option to disable) to turn off without a load or variation within 20 minutes.

Models are available with working load limits from 1 tonne up to 20 tonne and boast a 0.3% accuracy in the readings. The industrial load link is also IP 64 water resistant for protection in wet or humid atmospheres. The display window is built into the load cell and measures 18mm high so it is pretty easy to read.

Connections commonly used with these load cells are shackles and/or swivel hooks; Lifting Gear Direct can supply these too.

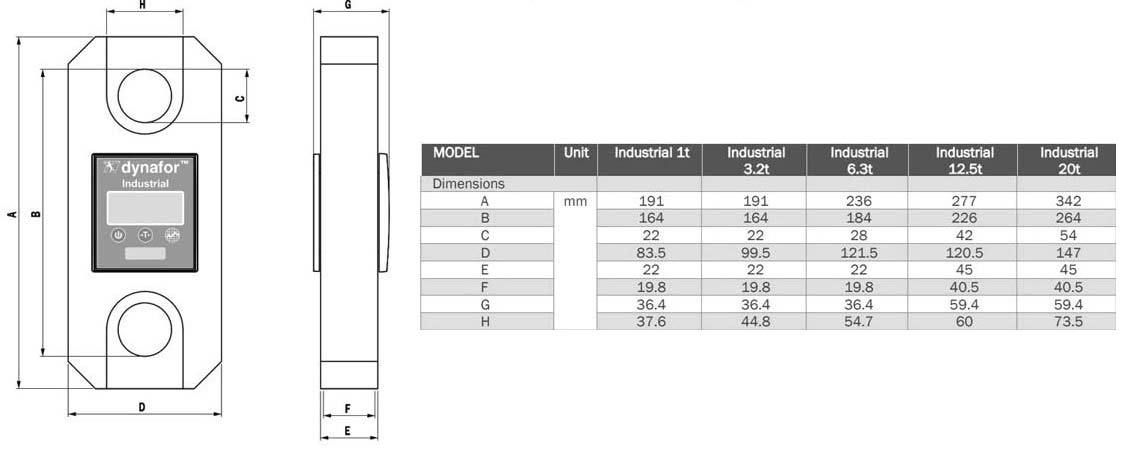

There are many more technical details for your perusal in the specification table in the tab above, here you will also find the actual dimensions of the load cell.

There are a number of other options similar to this load cell available here at Lifting Gear Direct, There are the Handifor, Pro & Expert load cell models from Dynafor as well as load cells from other brands such as Yale and Straightpoint, so there are plenty to choose from.

Crane scales are another load measuring option you may wish to consider; these come with their own display and connections and work great when used on a crane hook or similar.

Load and force measuring equipment plays an important role in the safety of a heavy lifting operation. When using this type of equipment you will al;ways know the exact weight of your load and the forces applied to the equipment when lifting the load.

| Model | Unit | Industrial 1t | Industrial 3.2t | Industrial 6.3t | Industrial 12.5t | Industrial 20t |

| Code | 260889 | 260899 | 260909 | 260919 | 260929 | |

| Max. WLL | t | 1 | 3.2 | 6.3 | 12.5 | 20 |

| Safety Coefficient | Minimum 4 | |||||

| Minimum load | 10% of WLL | |||||

| Precision | +/-% | 0.3% at 21°C full scale | ||||

| +/- kg | 3 | 9.6 | 18.9 | 37.5 | 60 | |

| Sample rate | Hz | 3 Hz – 32 Hz in peak hold mode | ||||

| Resolution | kg | 1 kg | 2 | 5 | 10 | 20 |

| Maximum display | % | 110% of WLL | ||||

| Digits height | mm | 18 | ||||

| Units | Kg / daN / lbs | |||||

| Conversion factor | 1 kg = 0.98083 daN = 2.20462 lbs | |||||

| Autonomy | hz | 250 | ||||

| Net weight | kg | 0.75 | 0.93 | 1.44 | 3.22 | 5.1 |

| IP protection | IP 64 | |||||

| Working Temperature | °C | -20°C to +50°C | ||||

| Sensor material | Aluminium | |||||

| Batteries | 3 x AAA | |||||