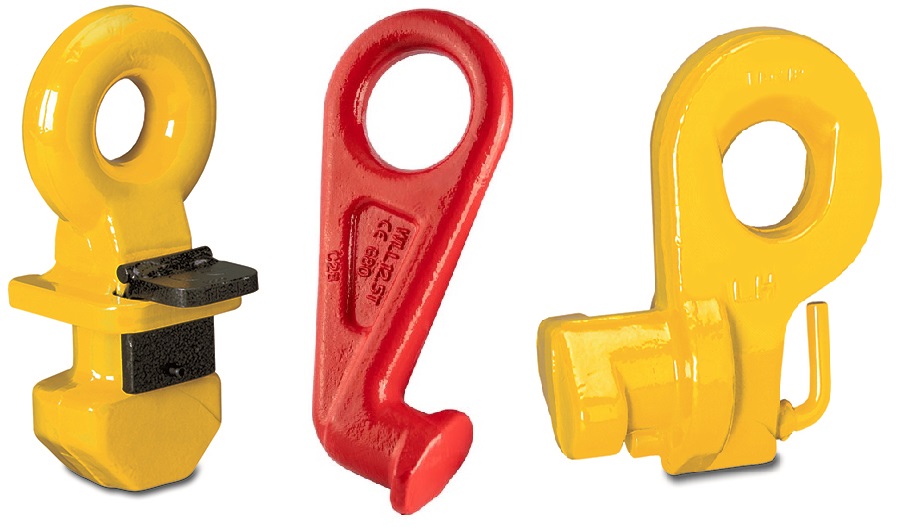

There are a few different varieties of container lugs for lifting and moving containers. Most are supplied in sets of four since that is how many you will need to lift a container, although our Cobra lug can be purchased one at a time should you require.

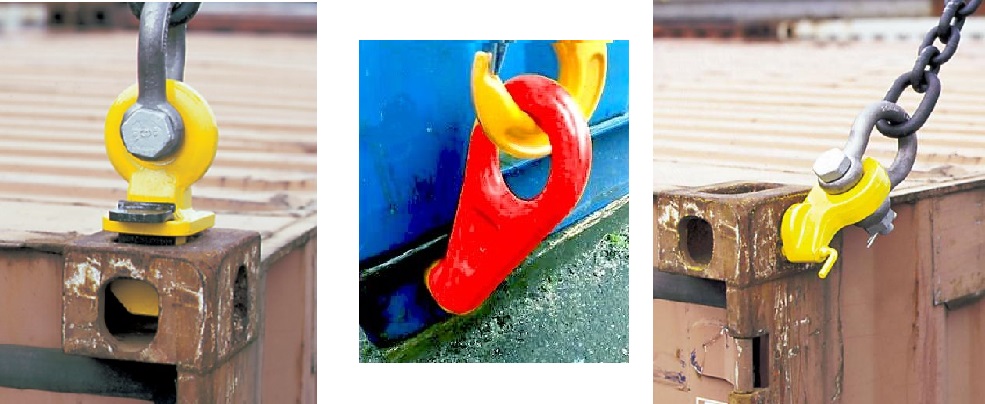

The Cobra lugs are for use on the side anchor ports of the container, NOT in the end holes.

The CLT container lugs are designed for top lifting via the top anchor port whilst the CLB container lugs can be used in the side lifting ports.

Each model comes with various safe working load limits which you can find on the specific product pages in the specifications tab. 56000Kg in the largest capacity lifting lug we can supply.

£687.90

About the CLT Lifting Lugs for Containers When it comes to lifting large stee..

£565.00

About the CLB Container Lugs The CLB container lugs are designed to fit to th..

£52.97

About the Cobra Container Lifting Lug The Cobra CLL lifting lug is one of the..

POA

Yoke Container Lug Details The Yoke Lifting lug may look like a simple device..

A container lifting lug has a single purpose and that is to facilitate the lifting of steel freight containers. They fit into the anchoring holes which are located in each of the 8 corners of a shipping container. The lifting lugs incorporate an eye which is where the slinging equipment will connect to which subsequently connects to a spreader and/or crane hook for lifting.

Steel containers are used for different things, they are most commonly seen at ports and docks as shipping containers however they are also used as freight containers on trains and transport lorries as well as storage containers, they are also often re-purposed as offices for the workplace.

Whatever the container is used for at some point it will need to be lifted and moved into place which would prove very difficult if not impossible without a set of container lifting lugs unless a large spreader frame is used like at shipping ports.

Four lifting lugs are used together with slinging equipment and often spreader beams to enable containers to be lifted with the forces applied evenly distributed. The container will remain stable and safe throughout the manoeuvre.

Quality chain slings with your choice of components can be supplied by Lifting Gear Direct where we will make up a sling, or set of slings according to your specific requirements. 1, 2, 3 and 4 leg chain lifting slings can be produced quickly with a 4 leg sling capable of being made to accommodate loads up to 31.5 tonne. We can also supply top branded lifting chain and components from the likes of Yoke, Rud, Pewag and Cartec should you want these.

As with all lifting operations using lifting slings safe slinging practices must always be followed and it is prudent to have some form of training. LOLER regulations should always be adhered to whilst making sure all lifting operations are safely planned and equipment used safely according to the HSE guidelines.

Container lifting lugs are used in sets of four and are locked into the designated anchor hole at each corner of a shipping container to provide a sling anchor point for lifting.

The majority of shipping type containers have no available anchor points from which to directly fit lifting equipment, however they do usually incorporate lug holes into the steel framework at each corner to provide a secure location to fit container lugs.

Container lifting lugs are used to lift shipping containers in a variety of ways. They can be inserted into the bottom holes for bottom sling lifting, in the top lug holes for top sling lifting or for attaching a top spreader frame for lifting heavy loaded containers.