Shipping containers and storage containers come in a range of sizes and whether empty or loaded they will need special container lifting equipment in order to lift and move them. The equipment used are typically container lifting lugs, chain slings or wire rope slings with shackles and hooks, spreader beams and/or a top lift spreader beam or frame. Carry on reading below to find out more or get in touch to buy today..

POA

About the CLT Lifting Lugs for Containers When it comes to lifting large stee..

POA

About the CLB Container Lugs The CLB container lugs are designed to fit to th..

POA

About the Cobra Container Lifting Lug The Cobra CLL lifting lug is one of the..

POA

Yoke Container Lug Details The Yoke Lifting lug may look like a simple device..

Container lifting is an arduous task and will need qualified riggers and rigging engineers to carry out lifting and moving containers.

There are numerous rules and regulations when it comes to lifting containers so follow the guidelines. How they are lifted will vary depending on the size and type of container, and of course its weight, loaded and unloaded. How the container is to be transported will also have an effect on the choice of lifting method; sea, road or rail are all viable means of transporting your cargo in these steel containers.

Steel Freight /shipping containers typically come in 10, 20, 30 & 40 ft lengths and are normally 8 ft wide.

There are different types of containers too! The most common types include open topped, some have fork pockets at the base, some have sides that open, some are refrigerated. Most if not all will incorporate a number of anchor points. These are usually around the top and bottom of the container.

There are a variety of ways to lift and move a container, how you do this will depend on the container style, where it is situated, where it will be moved to and the size and weight of the container.

Obviously a crane will be required to do the actual lift and move but perhaps the most important equipment needed will be the container lifting lugs. These lifting lugs create a strong anchor point between the container and the lifting slings. The container lugs fit directly into the load bearing recesses that are positioned at each corner of the shipping container, top and bottom making 8 in total.

The lifting slings that fit into the eye of the container lifting lug and are typically made of steel chain although sometimes wire rope cable is used. Then, depending on the lifting method the slings will connect to a spreader beam or frame which is subsequently fitted to the crane hook. The other way to lift and move a freight container is with a forklift truck. Many containers have fork pockets on each side so the trucks forks can be driven straight in. You will need to make sure the fork lift is robust enough to handle the container whilst remaining stable, and that the forks will fit the pockets.

The different methods of lifting and moving containers are used depending on the type, weight and size, and of course where it needs to be lifted from and too.

The four most commonly used methods of lifting are as follows:

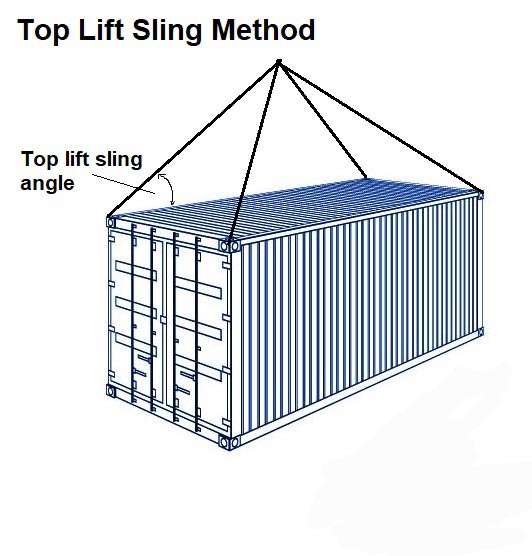

1, The top lift sling method.

This is perhaps one of the simplest container lifting method but should only be used for empty containers. This is because the lifting points are at the top corners so the sling angle will imply forces putting stress across the bottom/floor of the container and could cause it to split open if loaded.

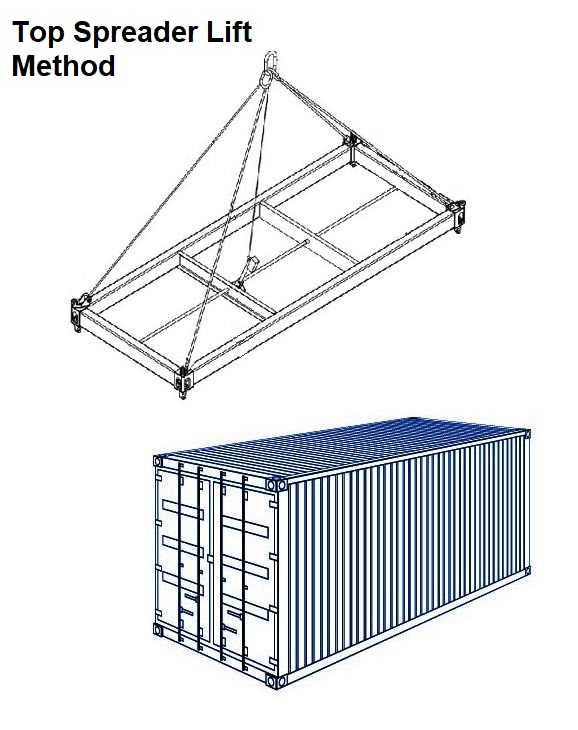

2, Top Lift with Spreader

When containers are

loaded with goods the top lift with spreader method can be used. This

incorporates a large spreader beam frame to span the full length of

the container. These can be manual or powered spreaders and whilst

the majority handle one container at a time some can handle multiple.

Once the frame and spreader are connected the slings fitted to the

top of the spreader will fit to the crane hook for lifting. The

spreader frame ensures no undue stresses are placed on the base of

container (as in method 1) as it spreads the forces out over a

greater area.

When containers are

loaded with goods the top lift with spreader method can be used. This

incorporates a large spreader beam frame to span the full length of

the container. These can be manual or powered spreaders and whilst

the majority handle one container at a time some can handle multiple.

Once the frame and spreader are connected the slings fitted to the

top of the spreader will fit to the crane hook for lifting. The

spreader frame ensures no undue stresses are placed on the base of

container (as in method 1) as it spreads the forces out over a

greater area.

This is probably the most expensive method due to the fact that it required a special spreader framework to anchor to the top of the container. However this is possibly the safest way to lift a container from the top and is most often seen at container shipping ports where hundreds of containers are offloaded from ships daily. In this scenario lifting from the bottom isn't an option because of how the containers are stacked tightly together.

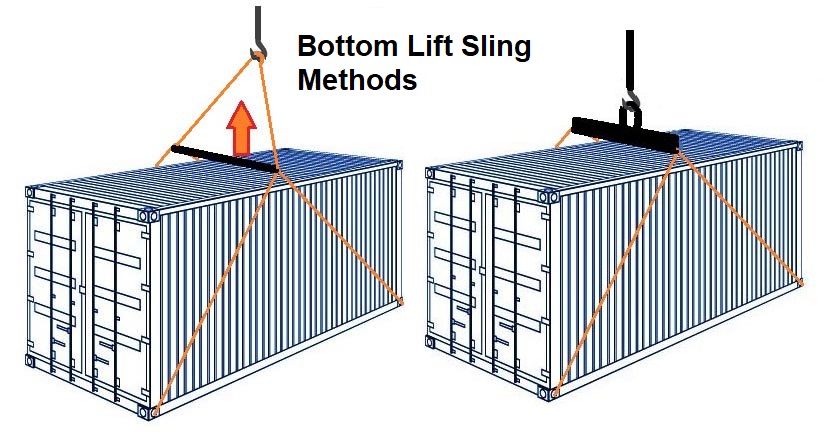

3, Bottom Lift with Spreader

This is the most stable

method of lifting and moving containers because the forces implied

during the lift are positioned at the bottom which is the strongest

part. Also because the lifting slings pass up the sides of the

container to offer more support. The sling will attach to a lifting

lug at the bottom corner and to a spreader beam above the container.

The spreader helps to evenly distribute the forces for better

stability. The spreader beam may have one or two anchor points –

one in the middle where you would fit the crane hook or one at each

end where an additional 2 leg sling will be fitted before the crane

hook.

This is the most stable

method of lifting and moving containers because the forces implied

during the lift are positioned at the bottom which is the strongest

part. Also because the lifting slings pass up the sides of the

container to offer more support. The sling will attach to a lifting

lug at the bottom corner and to a spreader beam above the container.

The spreader helps to evenly distribute the forces for better

stability. The spreader beam may have one or two anchor points –

one in the middle where you would fit the crane hook or one at each

end where an additional 2 leg sling will be fitted before the crane

hook.

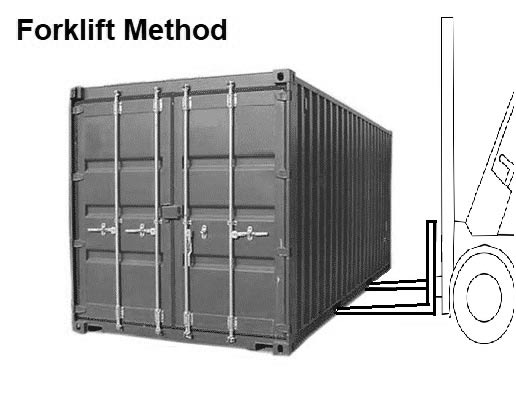

4, Fork Lift Truck Method

Many steel shipping /

storage containers incorporate a set of pockets into the base on each

side. These pockets are designed so that the tines of a forklift can

be driven directly into the pockets. The forklift can then lift and

move the container. However a forklift can tip over if not stable so

this method should be done with great care. You must also ensure the

truck can handle the weight, has excellent stability and forks that

will fit the pocket spacings.

Many steel shipping /

storage containers incorporate a set of pockets into the base on each

side. These pockets are designed so that the tines of a forklift can

be driven directly into the pockets. The forklift can then lift and

move the container. However a forklift can tip over if not stable so

this method should be done with great care. You must also ensure the

truck can handle the weight, has excellent stability and forks that

will fit the pocket spacings.

There are numerous guidelines to work to when it comes to handling containers . Freight container safety information can be found at the HSE where there are links to the SIP003 container handling guidance PDF compiled with the ports industry.

The lifting equipment used when loading and unloading containers will fall under the LOLER guidelines and must be inspected regularly.

Lifting Gear Direct can supply a range of container lifting lugs with a range of safe working loads. We are also able to supply chain slings and top branded lifting chains and components to suit your requirements as well as wire rope slings, all in single, double, 3 or 4 leg configurations. Please get in touch should you require any help.

A crane and sling system is used to load and offload shipping containers. There are different ways of doing this according to the type, size and weight of the container. The three main ways are the top sling method, the top spreader frame method and the bottom sling method. Find out more above.

Container lifting lugs are one of the most common methods of anchoring a sling to the container ready for lifting. These special lugs fit into the appropriate recesses at the corner points of the container, which ones will depend on the lift type chosen. Container lugs simply twist into place to secure them, the incorporates lifting eye is where the sling hook will be safely anchored.