ATEX lifting equipment incorporates a collection of different products that have been designed with spark-proof components to minimise the risk of ignition when used in potentially explosive environments.

Lifting Gear Direct can

supply a variety of ATEX rated lifting equipment for use in these

hazardous areas. We have a good choice of hoisting equipment which

adhere to the ATEX directive and are clearly marked with the identity symbol. Chain blocks, trolleys, lever hoists, air hoists and tool balancers are some of the products available with an ATEX rating. ATEX Height safety equipment is another area which

includes a number of rated products. But take a look at all of

our ATEX lifting gear right here to find the full collection.

Lifting Gear Direct can

supply a variety of ATEX rated lifting equipment for use in these

hazardous areas. We have a good choice of hoisting equipment which

adhere to the ATEX directive and are clearly marked with the identity symbol. Chain blocks, trolleys, lever hoists, air hoists and tool balancers are some of the products available with an ATEX rating. ATEX Height safety equipment is another area which

includes a number of rated products. But take a look at all of

our ATEX lifting gear right here to find the full collection.

POA

About the Yale ATEX Uno Plus Ratchet Lever Hoist The ATEX Uno plus lever hoist ..

POA

About the ATEX Retractable Tool Balancers When working with tools and handlin..

£451.50

Key Features of the Atex C4 Chain BlockThe C4 meets British standards to BS EN..

POA

About the Hacketts Push Travel Trolley WH-PTPrecision engineered to a high qua..

POA

It packs in all of the perks of the standard Yalelift 360 chain block&nbs..

POA

About ATEX Zero Gravity Tool Balancers For peace of mind these ATEX zero grav..

£84.55

Two size ranges are available to suit beam widths, the size A range isfor smalle..

POA

Yale makes a comprehensive range of lifting gear which goes far beyond man..

POA

About the Hacketts Geared Trolley – WH-GTEasier to use and position precisely th..

POA

About the Hacketts ATEX Pull Winch The ATEX ratchet lever hoist has anti-spark ..

POA

Its design means that it can be used in environments where combustible materials..

POA

About the Tiger Spark Resistant Lever Hoist Manufactured in accordance to the A..

The term ATEX is the

name which is commonly used for associations with the ATEX directive

requirements for keeping explosive

atmospheres

under tight control, including the suitability of equipment used in

them. Its name taken from Atmosphere

Explosibles has an easy

identifiable trade mark.

Normally used in conjunction with the dangerous substances and explosive atmospheres regulations (DSEAR) to control and minimise the risk of fire and explosions.

Any

atmosphere/environment which could potentially cause fire or

explosions must undertake all safety procedures set out by the ATEX directive and DSEAR.

Any

atmosphere/environment which could potentially cause fire or

explosions must undertake all safety procedures set out by the ATEX directive and DSEAR.

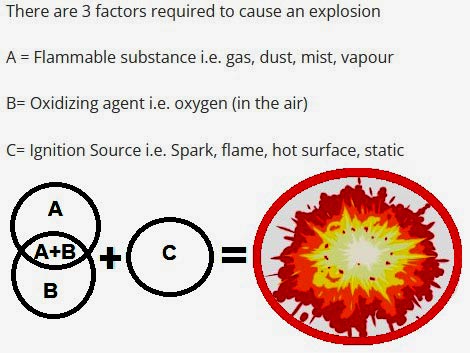

These conditions can be caused by flammable gasses, mists or even vapours and combustible dust particles. If any of these in enough quantities, when mixed with air come together with a source of ignition, combustion and an explosion is likely to occur.

Potentially explosive environments occur in many types of work places, including some that you would not necessarily think of as potentially hazardous. Any where that uses paints, varnishes, solvents and flammable gasses like vehicle spray painting for example, are some of the more obvious hazardous areas, but places undertaking sanding tasks causing wood particles , metal machining, causing metal particles, and even organic dust from food stuff like grain flour can all potentially cause major issues.

When you introduce certain equipment into these environments, it is usually these which are the potential source of ignition.

ATEX rated equipment eliminates the risk of sparking as the components that may cause this have been removed and replaced by non-sparking materials, and therefore minimizes the risk of a potential explosion.

Although this area is highly complex and you must independently undertake relevant research to ensure you are complying with the regulations correctly and therefore choose the correct piece of equipment, in short there are 3 key types of explosion protection under ATEX regulations.

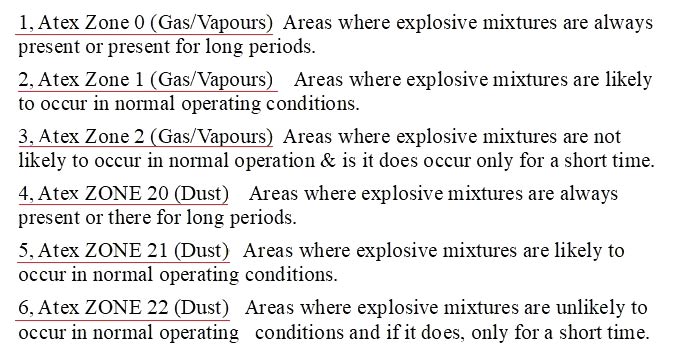

Potentially explosive atmospheres should be sectioned into 'zones' according to the risk factor and type. There are six zones in all with the first three relegated to gas and vapour type hazards and the last three relegated to dust type hazards.

Your ATEX lifting equipment should fit into one of these areas.

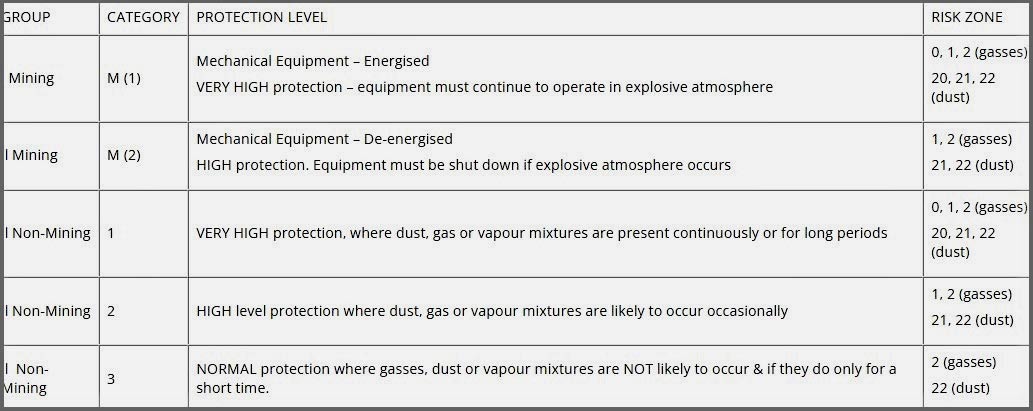

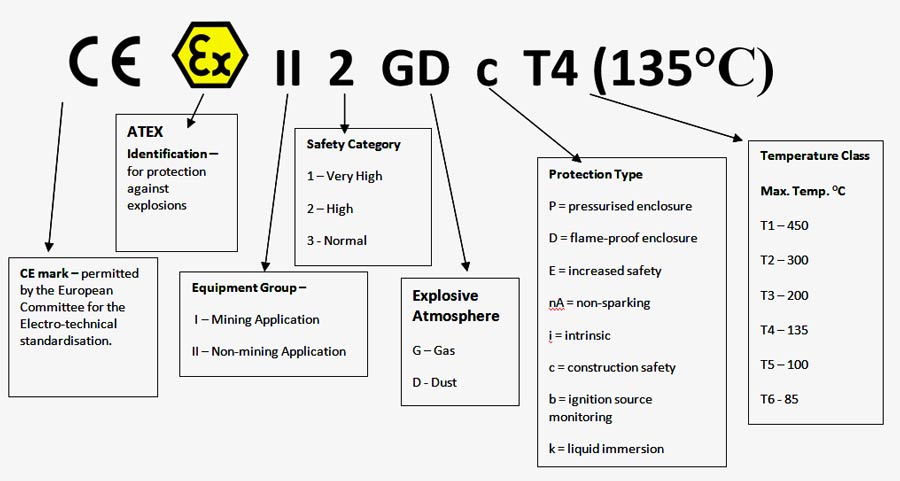

Further information in the following image shows the equipment groups, category, protection level and risk zone classifications

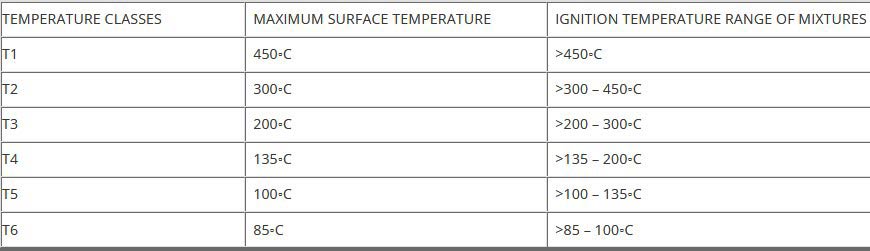

The temperature of of the environment can have a huge effect on the risk of explosions and therefore should be carefully monitored at all times. Here is some useful information regarding temperature classes.

If you are using any type of ATEX rated equipment it will be clearly marked on the device. This must be consistently readable so the user can identify where it can be used safely. The ATEX rating will show as a coded type marking, for example;

CE Ex l 3 GD c T6 (135°C)

Each part of this marking represents a different area of information, the next image shows how to interpret ATEX markings.

If you need equipment for use in potentially explosive areas it is your responsibility to ensure all necessary precautions are in place according to the right regulations, here we have just touched on the basics of ATEX principals and should not be interpreted that it will be right for all situations. Always do your homework and check out the latest guidelines from HSE.

Contact Lifting Gear Direct with any enquiries, our team are always ready to help.

Atex rated equipment meant that it is suitable for use in potentially explosive environments and follows the ATEX directive guidelines. There are a number of different safety zones which require different ATEX ratings so check carefully.

Atex rated lifting equipment differs from standard products in that it generally incorporates components made from different materials which will not cause sparking, such as copper plated load hooks.

Common ATEX zones are zone 0, 1 & 2 which are related to gas and vapour hazards, then zones 20,21 & 22 are for dust hazards. Find out more in the understanding ATEX zones section above.

Atex products are clearly marked with an Atex code, something like CE Ex II 2 GD c T4 (135ºC). Each section relates to a specific area, So CE is the CE mark, EX is the Atex identification, II is the equipment group, 2 is the safety category, GD is the explosive atmosphere type, c is the protection type, T4(135ºC) is the temperature class. Find out more in the table above.

We have a great selection of Atex rated lifting hoists including powered hoists and manual hoists. Beam trolleys, spring balancers and height safety equipment are also available in an ATEX format.