Customise your A frame gantry today with Lifting Gear Direct

Our extensive offering is almost unmatched, with everything from a 500kg A frame or a 1000kg A-frame - to our largest 5000kg gantry. Our load tested gantries are fully customisable to suit your requirements, there are a number of height, width and lifting capacity options as well as numerous add ons.

We are a leading UK manufacturer and supplier of gantry systems. Our custom-manufactured systems have both commercial and industrial applications, and our customers belong to a diverse range of industries. We have a reputation for producing high-quality lifting solutions at competitive prices whilst complying to the necessary regulations.

With a team of dedicated A-frame crane and lifting experts that are available to answer any questions, and the opportunity to buy complementary lifting equipment, it is no coincidence that we are the first choice for businesses and individuals alike when looking for where to purchase a gantry crane and other lifting gear.

Custom Gantry Enquiry Form£871.72

They can safely handle the lifting and lowering of loads up to 500kg but should ..

£1,089.74

1000kg Lifting Gantry Adaptations Large plated feet can be fitted during produc..

£1,714.26

2000kg Lifting Gantry Adaptability The 2000kg lifting gantry can be fitted with..

£2,213.31

3000kg Custom Lifting Gantry Benefits Fully tested and certificated you can be ..

£3,076.61

5000kg Lifting Gantry Performance Potential For obvious reasons the steel used ..

A gantry is a framework made from steel which has been carefully designed so that lifting equipment can be attached in order to lift heavy loads. This type of A frame can be fixed or mobile with the latter option being the most popular. Wheel the frame around your workplace to wherever heavy loads need to be lifted, then fitting and using a beam trolley and hoisting device you can lift your load and move it along the beam.

A gantry has many benefits, they are practical, versatile and strong, there are also many custom options are available when buying gantries manufactured by Lifting Gear Direct.

If you intend to use it in one position you could opt for the floor fixed option for optimum stability. However choose the heavy duty castor version and it becomes mobile. This enables more versatility as the structure can be moved around, inside or out. They can be erected fairly quickly by a couple of competent people and and forklift truck, they can also be taken down for storage or transportation in a vehicle if required.

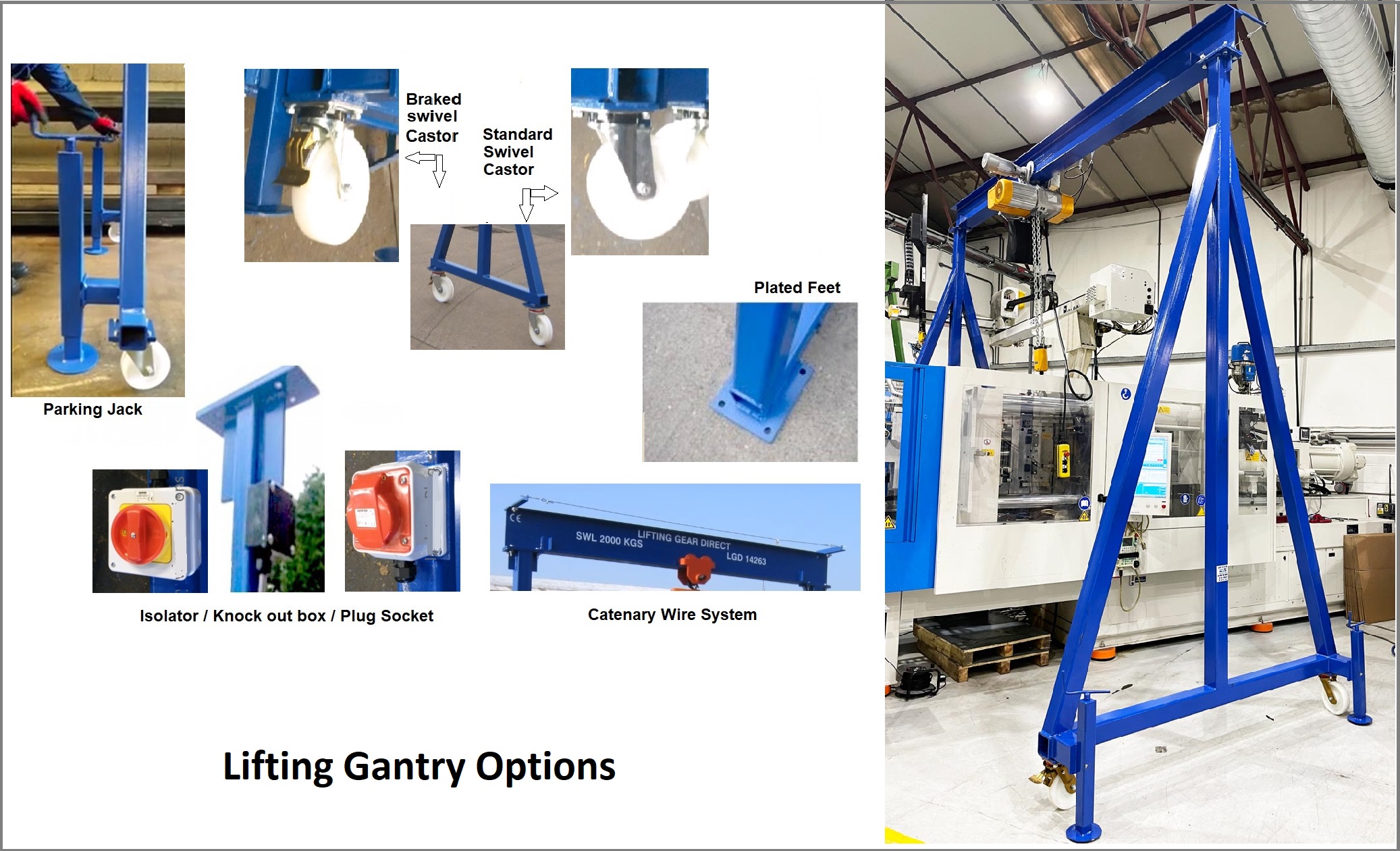

Your gantry system can be customised to suit your individual requirements. You can choose a specific span and under beam height for your crane up to and including 5 metres. Safe working load lifting capacity choices are 500kg, 1000kg, 2000kg, 3000kg or 5000kg. Once this decision has been made you should think about the mobility options; would you like your crane fixed to the ground (this option comes with plated feet for floor bolts) or mobile (this option has heavy duty, load rated castors, 2 are lockable as standard, all 4 is an option and provides optimum safety).

If you go with the mobile option then you may want to consider the parking jack add on. These are fitted to each leg (4) to add more stability to the structure. They can be individually adjusted which is ideal for accurate levelling when using on uneven ground. A level structure is imperative for safe use.

Other options which can be added to your a frame structure during manufacture include catenary wires and festoon systems which are ideal when using powered devices to hold cables out of the way. Isolator switches or knockout boxes are another add on to enhance safety when using electric hoists for example.

Lastly you will be asked if you have your own lifting equipment to use on the structure, Is it suitable? If not then we can supply for all your needs including beam trolleys, chain blocks, electric hoists, slings, shackles and more. Rest assured they will all be as keenly prices as possible.

Other options which can be added to your a frame structure during manufacture include catenary wires and festoon systems which are ideal when using powered devices to hold cables out of the way. Isolator switches or knockout boxes are another add on to enhance safety when using electric hoists for example.

Lastly you will be asked if you have your own lifting equipment to use on the structure - is it suitable? If not then we can supply for all your needs including beam trolleys, chain blocks, electric hoists, slings, shackles and more. Rest assured they will all be as keenly prices as possible.

The safe working limit on this particular lifting gantry is suitable for plenty of different lifting jobs, whether handling cargo and equipment or helping with at-height work. It may be relatively light and manoeuvrable, but this entry level model in the A Frame range is still sturdy, practical and versatile. Whether you want a portable setup or something a little more permanent, we can create the ideal package for you.

We can also add any of the following to your A-frame structure as extras:

1. parking jacks

2. festoon/catenary wires

3. electric isolators

4. Beam trolleys and any type of lifting hoist.

All of these extra are available as part of your order, or as separate components sold individually on our site. So even if you have an existing structure that you want to overhaul or enhance, you can do so with ease thanks to Lifting Gear Direct. Our cost-effective pricing and high levels of quality have made us a leader in this segment of the market.

Our gantries are delivered in three main parts; the top runway beam and two supporting A-frame legs. They are bolted together with four nuts and bolts at each end.

Due to the weight of the steelwork, forklift trucks will be needed to lift the parts into place safely.

Ensure there is plenty of clear, unobstructed space.

Using a forklift truck or crane, lift the top beam to the required height to suit the top of the A frame leg. (secure the beam to the forks or crane for safety and to prevent unwanted movement)

Using a second forklift or crane system with lifting slings, pull the first A-frame leg up to vertical and position under the top beam.

Line up the holes and insert the bolts, spring washers and washers then tighten the nuts. (ladders or a scissor/boom lift is recommended here)

Repeat step3 & 4 for the second A-frame leg.

Fully tighten and double check all bolts then lower the forks and back the truck away leaving a completed, stand alone structure.

NOTE 1: If included you must ensure the castors are locked off and parking jacks are secured on each leg prior to assembly and during any future lifting task.

NOTE 2: If you are installing an electric hoist we recommend this is attached to the beam prior to it being lifted up with the forklift. This will save time and effort to lift and attach the heavy hoist later.

NOTE 3; Recommended Bolt Tightening Torques

M12 – 70Nm; M16 – 175Nm; M20 - 341Nm; M24 – 590Nm.

There are a number of important safety aspects to consider when using an A frame structure, here we look at some key points, for more in-depth safety data click here.

ALWAYS:

Check for issues prior to every use, check for loose bolts, twisted or damaged frame, issues with castors or parking jacks etc. Also inspect additional equipment that will be used.

apply brakes and parking jacks before beginning lifting operation.

Ensure the structure is level, using parking jacks as necessary if ground is uneven.

Position the structure directly over and above the load to be lifted.

Disconnect any power before moving to a new position.

NEVER:

Move a gantry whilst under load

Exceed the Safe working load.

Allow a load to swing unduly and uncontrolled.

Rotate loads unless the centre of gravity will remain constant.

Walk under a suspended load.

Place ladders or climb on an unrestrained structure.

Use a defective gantry or one with suspected issues.

All of our lifting gear is manufactured to the highest possible standards. All of our gantries are manufactured to BS 2853 and BS 2573 standards, load tested, CE marked, and appropriately certified. This means that they are guaranteed to operate according to best practices, and able to withstand the requisite weight and stress.

All lifting gear must be inspected annually to ensure that it still complies with industry standards and remains safe for use.

At Lifting Gear Direct, we provide inspection services and compliance testing for all of our gantries.

Our systems come in numerous sizes with their own benefits and specifications, here are some details on each, however you can find out the specific details on each respective model product page.

They are manufactured in our workshop to BS2853/BS2573, are CE marked and come with appropriate certification. This means you can be sure that each unit is built to the highest standards and guaranteed to operate as intended. We custom-build each unit to the specifications you require and can come up with a unique design if you need a very specialised A frame structure.

Remember that all lifting equipment has to be inspected annually to make sure that it is still safe and stable. We not only build our own systems but offer follow up maintenance services and compliance testing. You can also buy height safety equipment on our site to make sure that employees have the right kind of protection to avoid injury and incidents.

Our A-frame's consist of 3 easy to bolt together parts for your convenience. Although the most popular lifting gantries consist of castors, plated feet can be arranged if you require semi-permanent or permanent fixing to the ground. It is also possible to use a gantry on plated feet without fixing down; these will often require the use of parking jacks if used on un-even surfaces.

1000kg is the maximum safe working load limit for this model; and we can produce it with any span up to 5 metres long and heights up to 4.5 metres under the beam. The 1000kg A-frame structure can be supplied with either plated feet for semi-permanent fixing of with heavy castors for easier manoeuvrability.

We also offer other A frame structure models with different specifications and features, including compact 500kg units and much larger examples with load capacities of up to five tonnes. Each one is built to last, using the best materials and components available. We manufacture our own-brand products with the same care and attention to detail that you would expect from an internationally known brand, so you can order an A frame structure from us with confidence.

These gantries consist of 2 a-frames and a cross beam, all which simply bolt together, and so can also be dismantled with relative ease. Two or more people are essential to safely assemble the structure. The plated feet option of the 2000kg A-frame structure enables a more permanent fitting which could be useful if the structure is nearly always used in one precise position. Although the plates are usually bolted to the floor for extra stability, they do not necessarily need to be. The floor bolts are easy to remove should the structure be needed elsewhere.

The 2000kg capacity is enough to make this a common choice for our clients, giving you two tonnes of load-lugging power which is suited to a range of applications and straddles the line between pure strength and portability.

The dimensions of the 3000kg A-frame structure are mostly up to you, due to the fact that they are manufactured in our own workshop. However, there are some maximum measurements that we can allow, these are 5m span and 4.5m under beam height.

When we talk about the maximum height we are referring to the distance from the floor to the underside of the top beam, therefore this is the maximum lifting height you can achieve. When talking about the maximum span, we are discussing the maximum measurement in-between the two ‘A’ frame sides, therefore this will be the maximum working area of the beam, the overall span / width of the structure will be slightly larger.

Whichever type of crane, Jib or gantries setup you choose, you can be sure that it will meet anticipated standards for safety. There is no point risking injury when, with the right equipment at your disposal, your employees can become more productive as well as safer in their work.

We can fit the 5000kg a-frame with extra heavy-duty castors for mobility or plated feet for semi-permanent positioning. The plates are bolted down to the ground, though are easy enough to remove when required.

If not used with bolted down plated feet and using on irregular height flooring, we can add parking jacks to allow minor height adjustments to counteract any imbalance. This will help with lifting safety in a number of situations, whatever the terrain you encounter. A portable structure can be a major asset, so long as it is used correctly and inspected regularly.

If you will be using any electrical equipment on this A-frame then we can add a festoon wire to safely hold the cables and also an isolator switch for emergency situations. We also sell electric hoists, winches and other kit on our site that you can use in conjunction with this portable gantry system. Our competitively priced products come in all shapes and sizes, supplementing the already impressive features of our own-brand gantries.

The 5000kg A-frame structure has some maximum height and span dimensions that are allowed. The height is to the underside of the beam and available up to a maximum of 5 metres. The span is the measurement of the beam inside the legs / side frames, which is also 5 metres maximum. Therefore, the maximum internal measurement of the structure is 5 x 5 metres, so if you need the total width and height due to size restrictions the size of steel used will also need to be taken into consideration to determine to overall dimensions.

Please contact us for more information. You can also check out the other A frame structure products we sell, or examine the various jib cranes and heavy-duty load handling equipment on our site. Many models can be customised to your requirements, so you have the freedom to get a setup that suits you, rather than having to make do with a one size fits all which is not ideal.

Let us know of your individual requirements and we will manufacture an A-frame structure to suit your specific needs. Our bespoke design and building service means that your product will suit you from the ground up, rather than being a generic item that is not perfect for the jobs you need to tackle. Being able to choose between whether or not it is permanently fixed in position or endowed with casters or legs for added portability is just part of what we can deliver. Furthermore, the level of experience we have working with customers to create the perfect structure means that it is easy for us to help guide new clients who are not sure what they need.

We also offer full inspection services which are carried out by our trained inspection engineers, with certification for your health and safety records supplied. This is important for regulatory compliance, which should be a concern for any business that needs to use gantry systems and other equipment from this market. The full range of products and solutions we offer at Lifting Gear Direct will keep you in line with industry rules.

Call us on 01384 76961 if you are interested in purchasing custom gantries from Lifting Gear Direct. A member of our accommodating team will be more than happy to provide advice, guidance, further information, and pricing quotes as needed. And if you are at all uncertain about your prospective purchase, we can ensure that you are making a fully informed decision.

Yes we do. All our lifting gantries are made to order to your exact specifications with a great choice of options available.

Yes, we have a team of engineers who are able to come and install our systems should you require, however it is often the case that you can do it yourself thanks to our bolt together system. If you require permanent floor fixing then we can accommodate this.

The largest structure that Lifting Gear Direct manufacture has a 5000kg safe working load.

We have a good range of dimension options for our bespoke lifting gantries. The maximum under beam height is 4.5 metres and the maximum span is 5 metres. Maximum dimensions may vary depending on the safe working load you require.